Learn about the Ender 3 Print Speed, how to maximize it (for free and for cheap), and what the best print speeds are for PLA, PETG, TPU, and other filaments.

Can you get a good print speed and good print quality from an Ender 3 series?

Yes… if you know how to calibrate it.

Ender 3 series 3d printers (Ender 3, Ender 3 Pro, Ender 3 Max, Ender 3 V2, and Ender 3 S1… then “neo” versions of all of those—listed from cheapest/oldest to most expensive & newest) are quite affordable… which means they also need some love out of the box.

My first 3D printer was an Ender 3 V2 and, after printing for a day or two, the first thing I thought was “how can I make my Ender 3 v2 print faster?“

Fun fact: as of this writing the fastest Ender 3 can print at over 1000 mm/s and print a Benchy in under four minutes instead of the typical 1.5 hours it usually takes.

But for those of us with a stock or slightly modified Ender 3, our print times are much, much slower than 1000mm/s.

So what’s the Ender 3’s print speed and what print speed settings should you use for the best print-to-quality?

The maximum listed mechanical speed of an Ender 3 series 3D printer (Pro & V2 included) is 200 mm/s. But the max actual print speed is often closer to 40 or 60mm/s depending on your material, line height, and nozzle size.

Let’s dig into why there’s such a difference between mechanical and actual print speeds.

Get the Ender 3 on Amazon for only $174.99

There is no ‘one size fits all’ print speed. This is because there are quite a few settings related to printing pace.

In most slicer engine software programs, “printing speed” is a setting that is used to calculate various settings that will decide how fast the nozzle will move.

Here we will refer to speed as the least amount of time needed to create a part when the machine is set to its fastest speed setting. Let’s assume we’ll use the default calculations to derive the other speed settings just like various other printers using a similar-sized printer bed.

What is the fastest the Ender 3 Pro, max, or V2 can print?

Creality lists the mechanical max print speed for a stock Creality Ender 3 3D printer as 200 mm/s.

BUT, the maximum print speed of any 3D printer is usually limited by the flow rate from your hotend.

Typical volumetric flow rates are 8mm³/s to 12mm³/s, depending on your hotend setup. These flow rates translate to 90-100mm/s and 140-150mm/s, respectively, at 0.2mm layer height with a 0.4mm nozzle depending on how your slicer handles the math.

The max speed also depends on the type of filament you use, your acceleration/jerk settings, what STL/model you’re building, and how nice you’d like the part to look.

But if you really want to have an incredible print speed, learn how to build a 1000mm/s Ender 3 for under $600.

What is the fastest an Ender 3 can realistically print?

The fastest you can print depends on:

- The filament you have

- The nozzle diameter you have

- The later height you’re printing with

For example, PLA would give you 60 mm/s while other filaments would have their own ranges. Keep scrolling for stock (0.4mm nozzle, 0.2mm layer height) speeds for your Ender 3 based on material or

Recommended Print Speeds for a stock Ender 3 (Pro/V2) with 0.4mm nozzle by material

Here’s a good starting point for your print speeds depending on the material.

| Material | Normal Print | First Layer | Fast Prints† |

|---|---|---|---|

| PLA | 45 mm/s | 20-40 mm/s | 80-140 mm/s |

| PETG | 35-45 mm/s | 10-30 mm/s | 60-65 mm/s |

| ABS | 40-60 mm/s | 20 mm/s | 60-70 mm/s |

| TPU | 17 mm/s * | 17 mm/s | Don’t |

| Nylon | 40 mm/s | 30-40 mm/s | 60 mm/s |

| PC | Don’t** | Don’t | Don’t |

| PEEK | Don’t** | Don’t | Don’t |

† Max flow rates can vary even if both are the same model. Keep scrolling for how to calculate the max flow rate (which is the most critical number to find your max travel speed).

* For printing TPU keep all speeds constant. Also, Ender 3’s use a Bowden tube – meaning there is a lot of distance between extruder gears and the print head for TPU to “lock-up”… so print slow and test thoroughly. See the printing with TPU section for details as it’s difficult to work with.

** Stock Ender 3’s, Ender 3 V2s, and Ender 3 Pros really can’t print PC, PEEK, or other high-temp filaments for two reasons. First PC and PEEK warp horribly unless you have an enclosure that can hold the part at least 80°C. Second, the melting point of PEEK is roughly 343°C and PC’s melting point is typically at least 270°C but the max (safe) Ender 3 nozzle is ~240°C.

Want to go faster? Learn how to build a 1000mm/s Ender 3 for under $600.

WHAT IS the best ender 3 print speed for PLA?

When using a 0.4mm nozzle, most of my normal PLA prints are printed at 60mm/s on the perimeters, 25mm/s for small perimeters, 35mm/s for external perimeters, and “200mm/s” (which ends up programmatically limited by Prusa Slicer to ~100mm/s) for infill.

PLA prints well at speeds between 30mm to 90mm per second. For high-quality results stick to lower printer speeds – around 30-50mm/s. As you increase the speed you begin to risk reduced quality prints when printing for high detail. This is because high-speed printing tends to create resonance (known as ghosting or ringing) that shows up in your prints.

PLA is typically the first (and often the best) filament you’ll print with. It’s derived from plant starches and smells like cooked pancakes.

PLA is also dead-easy to print with. It doesn’t really warp, it doesn’t take much to keep it from stringing, and you can fix mistakes rather easily.

What’s the best Ender 3 print speed for TPU/flexible filament?

Printing TPU on an Ender 3 V1, Max, Pro, or V2 is possible but challenging. Keep all speed settings constant at 15-35mm/s and calibrate with a temperature tower before starting.

This is because TPU and other flexible materials are soft and flexible so they’re more difficult to “push”.

Also, stock Enders (until the “Sprite” hotends found on the S1 series onward) use a Bowen extruder instead of a direct drive.

Imagine trying to push al dente spaghetti through a long straw… that’s what a Bowden extruder is trying to do with TPU on your Ender.

To avoid bunching and added friction you want a smooth, steady “push” so plan on printing flexible materials slowly, sometimes as low as 15 mm/s up to 25 mm/s.

Here’s a great recommendation for pristine TPU prints on an Ender 3, posted on Reddit:

So, should you print TPU on an Ender 3 (V1, Max, Pro, V2)?

Absolutely! TPU and flexible filaments are great for functional parts such as grommets, gaskets, rubber stoppers, and more. It can be challenging but the additional functionality it offers is unbeatable.

Just take a look at a simple TPU bumper that I quickly printed which is keeping my refrigerator door from being damaged by my oven handle. Simple, functional, fast. TPU.

Check out our favorite flexible filaments here

Ender 3 print speeds for PETG

PETG (aka PET-G) is a 3D printing filament that prints at a higher temperature than PLA. It has fantastic mechanical properties (similar to ABS) but the print difficulty is only slightly more difficult than PLA.

As a general rule, print PETG at roughly the same pace—or slightly slower—than PLA. If you create basic objects at low res you should be able to print as fast as 60 mm/second.

However, the best pace for PETG is typically around 40 mm/s since PETG can be a bit stringy.

You can usually eliminate stringy-ness by slowing your print speed.

best Ender 3 print speeds for abs

I have struggled to print ABS on my Ender 3 due to the lack of an enclosure. With that said, ABS prints at higher temperatures; increasing flow and reducing friction.

For a stock Ender 3 I’d recommend 40-60 mm/s for your print speed starting point.

However, this study showed that the best mechanical properties for FDM printed ABS is found at 70 mm/s (Rezaeiana et al., 2021). From the paper:

According to the experimental results, the fabricated specimens with a printing speed of 70 mm/s shows the best performance with the maximum elongation and fracture resistance compared to the other printed specimens with different nozzle speeds.

Rezaeiana et al., 2021

ABS can be a bear to stick to the print bed. If you’re having difficulty with warping be sure to print your first layer slow, turn on “draft shield” (if you’re using Prusa Slicer), and move your 3D printer away from drafts/airflow and into the warmest room of your house.

Oh… and be sure to have good ventilation.

ABS fumes emit both ultrafine particulates (UFPs) and volatile organic compounds (VOCs)—although this study states that they were both relatively negligible (Farcas et al., 2020).

What Factors affect print speed?

Apart from the filaments used, many other factors are responsible for printing speeds.

How acceleration and jerk affect your Ender 3’s Print Speed

Acceleration and jerk are often ignored outside of the Voron community. Yet acceleration and jerk are absolutely critical in reducing the total print time… which is really what we’re after.

Why?

Let’s say you set your print speed to be 200mm/s but most straight-line prints are a centimeter or two. In this case, the hotend assembly can never actually accelerate to 200mm/s before having to decelerate for the next turn.

Acceleration in 3D printing is exactly what it sounds like, but Jerk in 3D printing is different than in physics.

In 3D printing, Jerk is the maximum speed that the print head can be traveling before changing directions. It effectively ‘clips’ the remaining deceleration and just starts accelerating in a different direction.

Both of these have massive impacts on reducing your total print times, so they’re worth tuning.

how the Size and Complexity of the Model affects your ender 3’s print speed

Imagine trying to paint the Sistine Chapel in a day. To print detailed models you’ll need to slow your print speed to reduce artifacts such as ringing and ghosting.

For an Ender 3 (pro/V2) plan on 40 to 50 mm/s for detailed builds or as high as 70 to 80 mm/s for rough models and builds.

how Your ender 3 Hotend affects your print speed

Print speeds are limited by physics, namely, how much filament can you melt and solidify in a given amount of time. This is known as volumetric flow rate and is your real physical limitation on print speeds.

More on that in the next section.

how your Slicer settings affect your ender 3’s print speed

A few settings make a huge difference on print speeds and print times. Layer height, number of perimeters, and amount and type of infill are major culprits.

Perimeters generally print slower than infill. Having too much infill adds weight, time, cost without much gain. And types of infill can make a massive difference in print speed. And, if you’re increasing infill for strength, consider increasing perimeters instead. Like an I beam, it’s the “outsides” that matter more when it comes to strength.

How to make the ender 3 print faster (without upgrades)

There are two major ways to decrease your print times and increase print speed:

- Increase volumetric flow rate

- Adjust your model settings

200mm/s is not really your print speed, it’s a movement speed… even when printing.

When trying to print faster, it’s critical to focus on how much filament your printer can put down per second. This is known as the volumetric flow rate.

For example, a 1.6mm nozzle printing at 20mm/s will put down exactly as much filament as a 0.4mm nozzle printing at 80mm/s.

So, to print as fast as possible without upgrading you must:

- Calculate your maximum flow rate (which will be different for each printer) then

- Calculate your maximum print speed – or linear speed – based on the max flow rate.

How to calculate the max flow rate for a stock Ender 3 (v2/pro)

To find the max speeds for your printer, you need first to find the maximum volumetric flow rate for any given combination of nozzle size, material, and speed. You first pick a filament and temperature, then manually feed Gcode to your printer pushing more and more filament until it eventually starts clicking.

Why do this?

Every hotend is limited by how much energy (heat) it can send to the filament to melt it.

Hotend temperature will temporarily drop if you try to shove filament through faster than the hotend can heat it. When the hotend temp drops you’ll get under-extrusion, extruder clicking, and uneven print widths.

It’s gonna be a bad time.

For a very detailed walkthrough and discussion of testing methodologies, see Bob’s project notebook on calibrating volumetric flow rate.

Calculating your max print speed from the volumetric flow rate

Now that you know your maximum VFR, here’s how to calculate your maximum linear print speed from your volumetric flow rate

Total Time: 1 minute

-

Find your layer height and extrusion width (not nozzle width)

In Prusa Slicer you can command/control + f (to search) and type “extrusion width” to find your settings.

I use the largest width (Prusa allows for different widths depending on line type – aka external perimeter vs infill) to be sure that I don’t under extrude a feature.

-

Divide Volumetric flow rate by line height

Be sure to keep units consistent – so this should be mm (usually 0.2mm for drafts/quick prints, 0.1mm to 0.15mm for finer detail)

-

then divide that number by the extrusion width

It’s important that you use the extrusion width, not the nozzle width, as this is the actual flow of material leaving your hotend. Again, be sure to use consistent units (mm, typically)

-

You’re done

Your result should be roughly 100mm/s, up to 200 and not likely below 80.

If your result falls outside of that and you started with 8-12mm^3/s then check your math.

For reference, the math is:

Linear speed (mm/s) = VolumetricFlowRate(mm^3/s) / (lineHeight(mm) * extrusionWidth(mm))

Adjust model settings to print faster with your ender 3 (pro/v2)

What upgrades will make the ender 3 (v1/pro/v2) print faster?

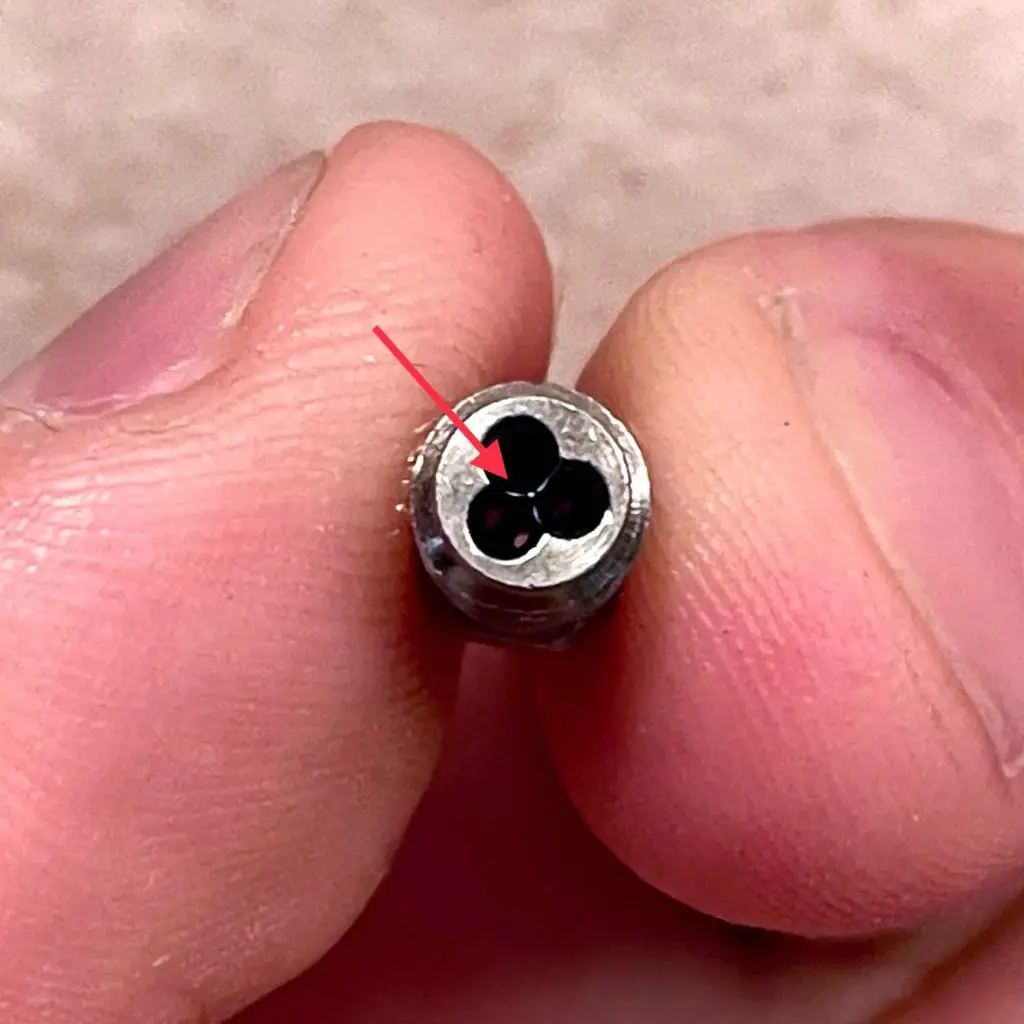

Bondtech CHT nozzle – $20 and 2 minutes for 30% faster Ender 3 print speed

The cheapest and fastest way to improve print speed is to get yourself a CHT nozzle. They split filament into three parts – allowing faster heating of the filament and increasing flow rate by 30%.

For $20 – it’s the fastest and cheapest way to boost print speed. They’re also offered in MK8 (Stock Creality) and RepRap (aka M6)… though the MK8s are harder to find and the stock Creality hotend is a great thing to swap out.

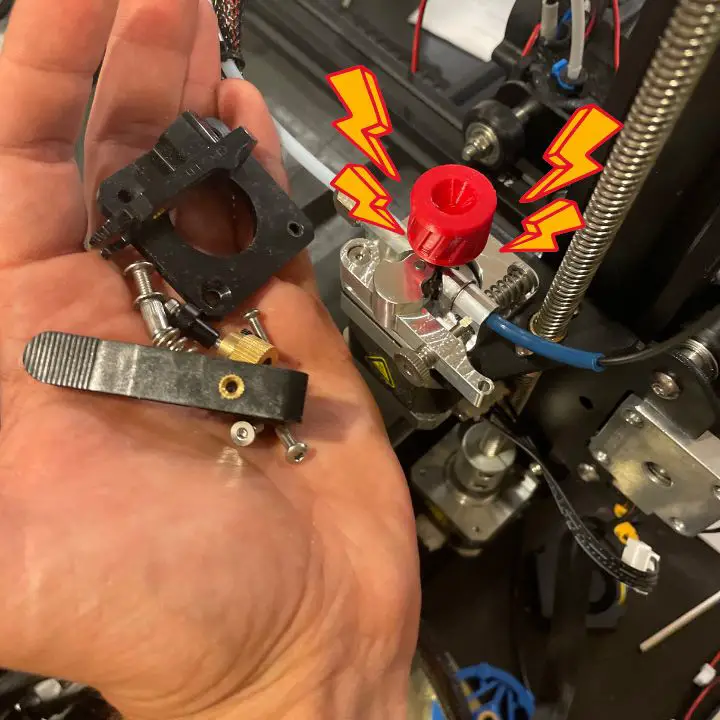

All metal extruder to juice your ender 3 print speed

Next up, ditch your plastic extruder with the stock Creality gears. You have a lot of options, but I went with the Micro Swiss Bowden Dual Gear Extruder.

How fast can the Ender 5 print?

A well-calibrated Ender 5 can print at linear speeds of 80-120mm/s. This is because the Ender 5 is nearly a CoreXY setup, where the bed only moves up & down (the Z axis) and the print head moves in the XY plane.

This allows for faster print speeds as the actual printed item stays still.

It also means that you’re not slinging the bed around, which for an Ender 3 weighs nearly 1 kilogram (the glass alone is ~500g). Not an issue at low speed but a major issue when printing fast.

Due to the CoreXY-ish setup, the printing pace of the Ender 5 is faster than the Ender 3 series counterparts.

Depending on the material you can usually print good quality prints at around 80mm/s and craft high-quality models without compromising the overall quality of your prints.

In summary

There are no universal speeds for 3D printers and the general rule is “slow” (~40mm/s).

They are dependent on the filaments and personal quarks of the specific printer when it comes to build times.

To optimize the pace of your printer, keep the machine well-tuned and experiment with it to find the optimal settings for your 3D printer.

Also, if you want to increase your print speed be sure to:

- Measure and set the actual average diameter of your filament,

- calibrate your e-steps,

- calculate your max volumetric flow rate (see above),

And it wouldn’t hurt to print a better part-cooling system.

Good luck and be sure to check out our build where we’re aiming to print at over 1000 mm/s for less than $600 including the cost of the printer (or, at least print a benchy in under 10 minutes for that price).

What is the best speed for 3D printing?

The best speed for 3D printing will depend on your printer type (bedslinger, fixed bed, core-xy, delta), hotend, flowrate, printer stiffness, filament type, etc. But, in general, the best speed for 3d printing—balancing quality and speed—on a stock printer is between 40mm/s–60mm/s

Should I 3D print at 100% speed?

Yes. In general you should be setting your print speed in your slicer, not on your printer. Plan to use the printer-based speeds when you hear clicking/skipping mid-print and don’t want to re-slice the model.

What’s the Ideal print speed for the Ender 3 (pro/v2)?

I’ve found that with PLA and PETG, the ideal print speed for the Ender 3 Pro and V2 is roughly 50mm/s. This balances both speed and quality, generally avoiding ghosting.

Assuming you haven’t upgraded your hotend, of course.

What is the fastest Ender 3 Pro can print?

The fastest Ender 3 Pro can print is 250mm/s on a stock Ender 3 Pro. At that speed your print speed will be limited by volumetric flow rate, quality, and the boards’ ability to take commands that fast.

What is the fastest the Ender 3 Printer can realistically print?

The fastest a stock Ender 3 Pro can realistically print is 100mm/s if printing at 0.45mm widths and a 0.2mm height—limited by its ~9mm/s^3 volumetric flow rate.

What’s the best ender 3 travel speed?

150mm/s. Even my most modified Ender 3 printer’s travel speed is only 200mm/s. Travel speed rarely slows down prints by much and isn’t worth over-stressing your printer to shave a few seconds off your print time.

You’re estimates seem very low. I routinely print PLA with my Ender 3 Pro (properly calibrated esteps, linear advance, etc) at 150 mm/s and achieve exceptional results.

Thanks for the heads up, Greg. I’m the new owner of Makershop and am working on cleaning and updating content. Got a reference for us to link to on calibrating so we can hit 150 mm/s?

Thanks mate!

Went back and re-wrote the article. My Ender 3 V2 is pushing ~12.8 mm^3/s. At a 0.45mm extrusion width and 0.2mm height, that gives me a max linear speed of 142mm/s. To get past 150, I’d have to reduce the layer height (0.16mm H = 177mm max speed) or nozzle width.