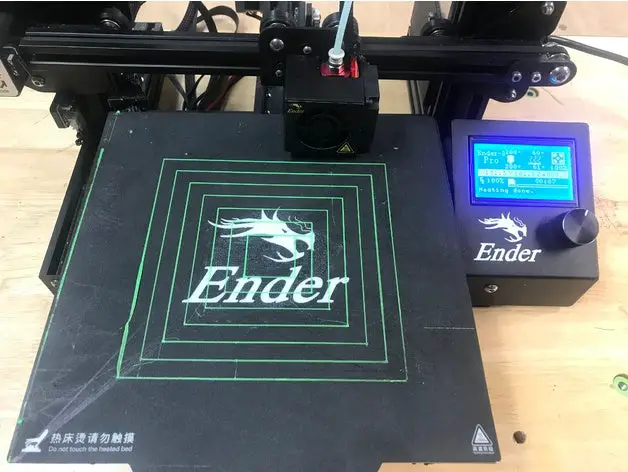

The Creality Ender 3 series printers (including the Ender 3 Pro, Ender 3 V2, and Ender 3 s1) are incredibly popular 3D printers thanks to their ease of use and affordability. One of the reasons they are so appealing is because of their generous print volume and bed size.

The Ender 3 bed size is 235 x 235 mm, but the actual printable area is 220 x 220 mm x 250 mm. This is because there is a slight difference in the actual bed size and the area the nozzle can safely reach.

In this post, we’ll talk about why the print size and the bed size are different, and how you can push the limits to increase the printable area of your Ender 3‘s print bed.

Ender 3 Bed Size vs print volume

So the first thing to discuss is bed size and print volume.

Creality advertises the Ender 3 bed size as 235 x 235 mm. If you were to grab a measuring tape and measure the actual bed dimensions, it would indeed be 235 x 235 mm.

However, when you consider how far the nozzle can travel along the X and Y axes, you’ll see that it is limited to an area of 220 x 220mm.

For the X-axis, the nozzle is mounted on a rail, along which it is pulled back and forth using a stepper motor and a belt.

From one extreme to the other, the travel area is 220mm, hence the 220mm size.

For the Y-axis, the bed itself moves back and forth using the same stepper motor and belt mechanism. Here, the nozzle would remain in the same position but the bed itself moves back and forth – the back and forth motion is limited to 220mm.

Visualizing the difference between print size and bed size

If you already have an Ender 3(or any 3D printer) you can visualize this by homing the nozzle.

Go into your 3D printer’s menu and find the “home all axes” or similar function.

Once the homing procedure is done, you can measure the distance from the nozzle to the edge of the bed.

You can multiply this number by two to find the tolerance!

On an Ender 3, you’d find a difference of 7.5 mm between the nozzle and the edge of the bed on the X or Y-axis.

You need to double this number because this tolerance will be present on either side.

Another issue is that the build surface of the Ender 3 is attached to the print bed using binder clips. To get around this extra space, the print bed is set to be 14% smaller!

Pushing the limits

If you want to push the limits of your Ender 3 and eke out that extra 14% of space, you can modify the firmware of the Ender 3 and hardcode a larger print area into the firmware.

This will let your printer move the nozzle further and get you that extra space.

Here is an excellent guide to upgrading your Ender 3 firmware.

But beware, changing your Ender 3’s firmware is an advanced mod and you risk bricking your printer if you don’t know what you’re doing.

If you’re unsure and are not willing to risk your printer, DO NOT proceed!

Once the firmware has been modded, you can make some hardware changes to eke out the extra bed size on your Ender 3 3D printer.

First, you can remove the binder clips that come with the printer and use another way to keep the print surface attached to the bed.

An alternative is to upgrade the build surface to a magnetic print bed.

Upgrading build surfaces

A magnetic print surface for the Ender 3 is a superb mod you can do as you can just peel the print bed off, twist it and pop the print off, and stick it back on the bed.

Once you have the magnetic bed, you’ll gain the extra space you lost from the binder clips, and you can print larger parts.

Do you really need such a large print bed?

So far, we’ve talked about how to get an extra 14% printing volume from an already generous 220x220mm print bed.

So the question is: do you really need that extra 14%?

Realistically, most of the models you will ever print will be far smaller than an area of 235 x 235 mm.

Another issue with attempting to print such large objects is warping and bed adhesion.

Objects with a very large area are notoriously difficult to print, and you may find that halfway through your print, one corner has lifted off the print bed.

Yikes!

Most of the time, you’ll print much smaller objects!

One situation where you may require the most are possible is if you wanted to print multiple objects in a single print.

For example, if you were 3d printing a cable chain for your wires, you’d be printing multiple links. Obviously, you’re not going to print a single link every time, so you’re going to fill the entire print bed with chain links so that your printer can finish it in one print.

However, the issue with so many prints in one go is that if a single object fails, it will most likely ruin the other parts too!

Need more space?

If you still feel you need more print space, perhaps you need a bigger printer! With the Ender 3, you’re constrained to the maximum 235mm x 235mm bed size as the physical boundaries of the rails will prevent you from using a bigger bed.

For extremely large prints, you would need to purchase a larger printer like the Creality CR-10 or Tevo Tornado, both of which have a print area of 300 x 300 x 400 mm.

Rebuild your Ender 3

If you’re feeling even more adventurous and want more print volume, you could rebuild your entire Ender 3!

The only new parts you’d need are:

- A new frame(aluminum extrusions work great)

- Longer belts

- A large print bed

This is quite an extensive project, but you should be able to use most of the Ender 3’s parts and just replace the frame.

Cartesian and Delta print beds

While we’re on the topic of print beds, it’s interesting to mention the difference between FDM and Delta 3D printer beds.

Cartesian 3D printers tend to have square or rectangular beds and allow for a lot of 3D printing area with varied height.

Delta 3D printers have smaller build plates but allow you to go much, much higher. So if you’re looking to print very tall models, consider buying a delta printer

Delta printers are also much faster than Cartesian printers!

Conclusion

If you’re shopping for an Ender 3 or you have already bought one, the Ender 3 bed size may have been a little confusing to you at first.

As you saw, the 15% loss of print area is actually quite inconsequential for most prints, and you shouldn’t let this dissuade you from purchasing what is an overall awesome 3D printer.

If you already have an Ender 3 and are tempted to mod it even further, go for it! A large part of 3D printing is modding and experimenting.