3D Printing Cost Calculator Tool

Easily calculate your true cost, and profits, of 3D printing parts with this tool that analyzes your STL model, electricity costs, and more

This tool is designed to help calculate the "actual" costs and profits you can generate from a 3D Printed part.

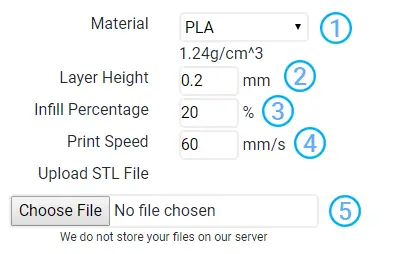

To use the 3D Printing Calculator enter the values below and upload your STL file. The calculator will slice your file and estimate the values needed to calcutae the cost of the print.

To fine tune and adjust the data below click on the setting button and adjust as needed.

How the 3D Print Cost Calculator Tool Works

Have you often wondered your true cost of 3d printing? If you have searched for a 3d print price tool or 3D print cost calculator then you have found that they are out there. But, most of them are either manual entry and are a ballpark estimate to what your real cost is of 3d prints.

We have put together this price tool to try and make it easy and accurate to price and calculate an stl file for 3d printing. Our calculator tool take into account what most online tools don't. Things like machine wear, maintence, bed type adhesion and an upload stl feature. We have also added a 3d print markup percentage, shipping and packaging option.

To fine tune your options simply click on the setting button and configure your preferences.

Using the 3D Print Cost Tool

- Select your printing material

- Specify the Print Layer Height

- Input the Infill Percentage of the Part

- Enter your Print Speed in mm/s

- Upload your STL File to generate part cost.

Important Factors when Calculating the Cost of a 3D Print

Here are some of the important factors this cost calculator uses to create the cost of printing an stl file.

Electricity Rate ($)

Probably the most obvious it items involved is the price of electricty the print uses in order to complete the file. You can find this information by search engine or if you live in the United States you can refer to this chart Electricity Rates by State and find your states rate per kW/h. This will be the driving force behind how much it costs you to print 3d models. A nice way around this is to invest in Solar for you home. A great way to do this is to check out OneClickSolar where you can get free instant quotes online for residential solar installations.

Setup Fee and Labor

How long does it generally take you to load an stl file into your favorite Slicer, setup the gcode and prepare your 3d printer for printing. This is what the Setup Fee is for and this time about adds up significantly over time. We added this as it's own field as larger more complicated parts take more time to prepare.

Labor can also play a role in the actual cost of a 3D Print. For example; if the stl file you would like to print has a lot of support material that take a long time to remove, then this time should be factored into the cost to print. Things like rafts, skirts, supports and other areas of post printing can be calcuated in this field.

Shipping and Packaging Material

Okay so this one is pretty obvious but a lot of online 3d print price tools do not have this added option. This has separate areas for packaging material like boxes, padding and invoices as well as the actual cost of shipping with the carrier.

3D Printer Maintenence

This factor is most often overlooked and really can play a role in high volume production machines. Although 3D Printer parts can last a very long time, things will eventually fail. Including this into the cost helps pay for and maintain important parts over time. This can really help dial in the price when using high end accessories like Micro-Swiss Products or the The Olsson Ruby.

Upcoming features will add more selections on these 3D Printing components.

Bed Adhesion Method

There are so many ways to improve bed adhesion. From the infamous Blue Painters Tape to products like BuildTak which I see more 3D Printers coming with OEM more than ever. We recommend using GizmoDorks PEI with 3M adhesive backing as we have found this to be the best solution all around for getting your 3D Prints to stick.

This 3D Printing Cost factor can add up over time. Especially when using hari spray, glue stick or tape which have a higher replacement and installation rate.