As far as slicer engines are concerned, the Ultimaker Cura is arguably one of the single most popular and commonly available programs out there.

It’s what I learned on and, even though it’s both free and open source, Cura is also absolutely loaded with tons of great features. Let us take a quick look at an entirely new and really cool kind of infill pattern available with Cura: Gyroid infill.

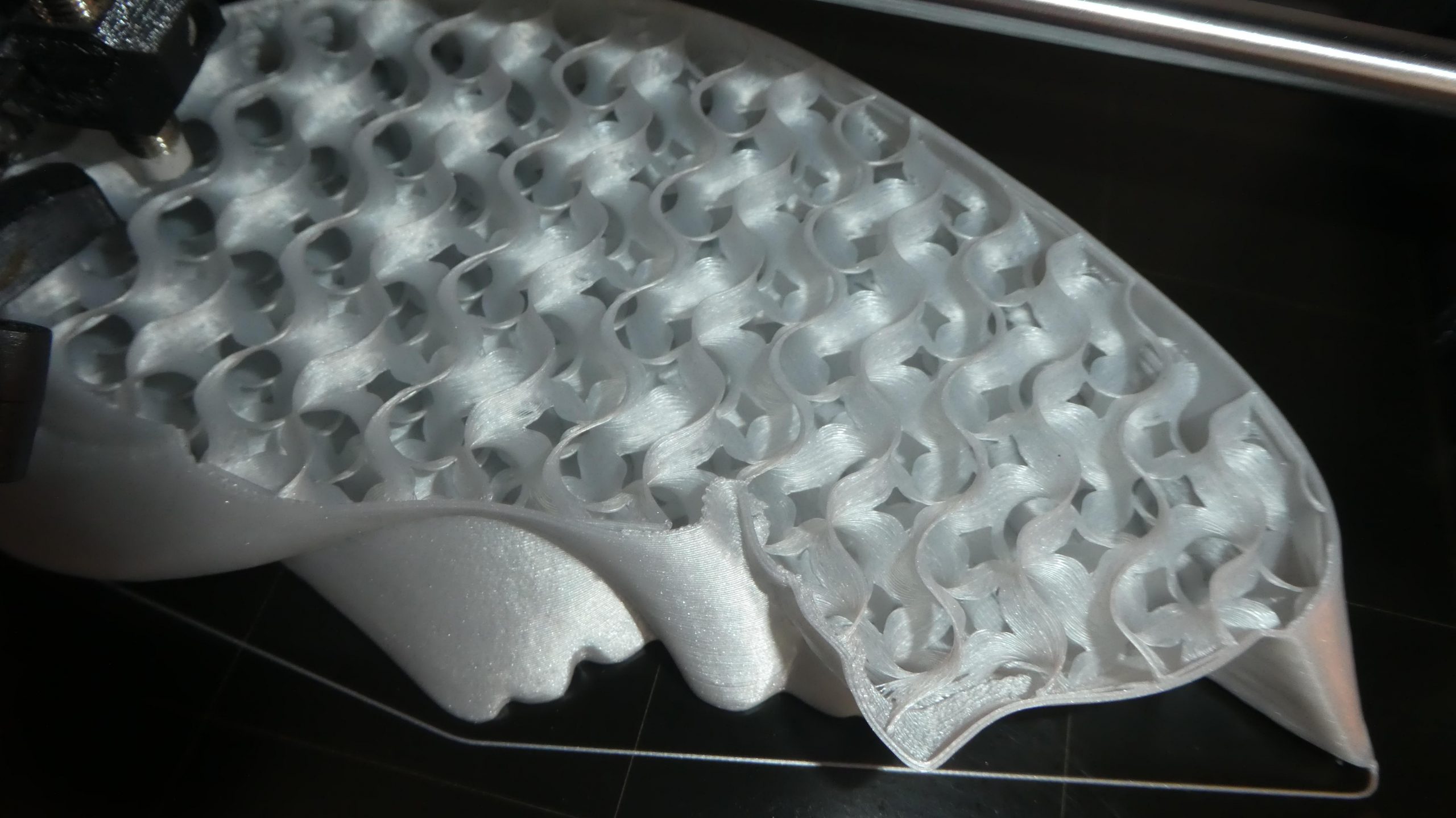

Image credit: Reddit

What Exactly Is Gyroid Infill all about?

Gyroid Infill, as the very name suggests, is basically concerned with the inside of any 3D model that you want to build. In 3D printing, the infill feature enables you to vary the precise density of the model even as it helps to maintain the overall strength of the structure.

Here, Cura’s multiple infill options are a great way of experimenting with your build. This means that you will be able to find the very best Cura infill pattern regardless of whatever it is that you wish to print.

Using Cura’s Gyroid Infill Feature

You can find the Gyroid 3D printing infill patterns at the front of the honeycomb style infill settings tab of the Cura slicer engine. Or even slic3r.

There is no rocket science to it and it’s a pretty straightforward way of infill printing. In fact, once you activate this feature you will be able to print it just like any other sort of pattern. However, it is pertinent to note the following points here:

Better Infill Density

With Gyroid 3D infill patterns, the main advantage is that you will now be able to print with a markedly lower infill percentage and thus save on filament costs. Yet you will still be able to get very good results indeed. Here, an excellent starting point would be an infil of approximately 2 to 3 percent.

What Infill Percentage Should I Use For Best Results?

When operating your machine at standard densities, it is imperative that you start off with an infill speed of around 50 mm per second. Only then should you try to work your way up from there. This way you will eventually find the best speed that will suit all of your needs.

However, here it is important to understand that whenever you start printing with a considerably denser infil percentage, it will always be the standard best policy to keep the overall printing speed as slow as you can. Otherwise, it will lead to the printer vibrating very rapidly and this in turn, will create plenty of problems with your 3D print.

Benefits of Using Gyroid Infill

There are plenty of advantages of using the Gyroid feature and it confers a veritable host of benefits to any object created with the help of this Cura feature.

Is Gyroid Infill strong?

The answer to this question can be seen in the following advantage of this feature:

Greater Shear Strength

As a general rule Gyroid infill is almost always a whole lot stronger than any conventional 3D printing infill types that you can see and share online. This is due to its higher 3D printing infill density. Moreover, it also has much faster printing times when compared to many other infills.

It has been said that this particular infill feature has been inspired by an MIT study conducted in 2007. The top researchers of the institute designed one of the lightest and strongest materials available in the modern world while using Graphene. Curiously enough, the tensile strength of the object so created was not due to the material used, but rather by its gyroidal shape.

What Is The Strongest Infill?

MIT technicians found that the very shape of the Gyroidal infill is almost entirely responsible for its extreme shear strength rather than the material used in its construction.

One reason it’s the strongest infill is that it is a naturally occurring pattern found in nature. From butterfly wings to human cell membranes, the strength of our bodies also depend on this shape to a large extent.

In fact, it won’t be wrong to assert that this finding basically generated a whole lot of interest in the world of 3D prints. Inspired by this research, the good people at Cura also added their own Gyroid feature to their existing patterns. Thanks to this infill, it is now possible for most users to print much stronger as well as lighter components.

Low Weight

The weight to filament ratio becomes extremely low when using this pattern, especially when using it with a Prusa Printer. There are a lot so of posts online and those have been posted by people who have great results with this pattern. This way it will be easier to save up on expensive filament costs without compromising on the structural integrity of your build in any way.

Faster Printing Time

Gyroid infill will almost certainly print much faster when compared to most other types of patterns. This is due to the fact that it has certain isotropic properties that make it the fastest infill pattern around. In other words, the infill will be uniform in all of its orientations.

In the long run, this will make it highly suitable for all sorts of flexible prints. This makes it faster than rectilinear infill patterns. (If you are not sure you can post online to find people who know about this.

No Crossover in The Same Layer

Another unique but oft unmentioned advantage of the Gyroid pattern is that, unlike cubic infills, the Gyroid pattern never really crosses itself in the same layer.

This is sometimes a bit of a problem with Cubic infills because they can lead to excessive use of an expensive filament.

It Is Versatile and Flexible

Once the 3D printed object is complete, it is very easy to go ahead and backfill all the empty spaces that are located within the Gyroid with both lighter and cheaper materials. You can even use epoxy for this purpose. This will give your build plenty of versatility as well as the flexibility.

It looks Beautiful

Finally, a Gyroid shaped pattern looks both beautiful and fascinating to any onlooker. It can captivate the attention of anyone who sees it, especially for the first time.

Disadvantages of the Gyroid Infill Pattern

While it’s true that Gyroid infill is one of the very best infill patterns around, it has two major disadvantages:

- Printer vibration can become much higher and they can increase to almost unacceptable levels due to such dense infill percentages

- Long, long slicing times

Conclusion

Despite printer vibration issues and long slicing times, Cura’s Gyroid infill excels at shear strength and flexibility.