Today we’ll be looking at the benefits and drawbacks of the two types of extruders found in Fused Deposition Modeling, Bowden tube and Direct Drive extruders.

The key difference between Bowden and Direct Drive extruders is where the stepper motor and feed gears are located – for Bowden it’s on the 3D printer’s frame VS above the hot end for Direct Drive.

Bowden Extruders

What’s a Bowden configuration?

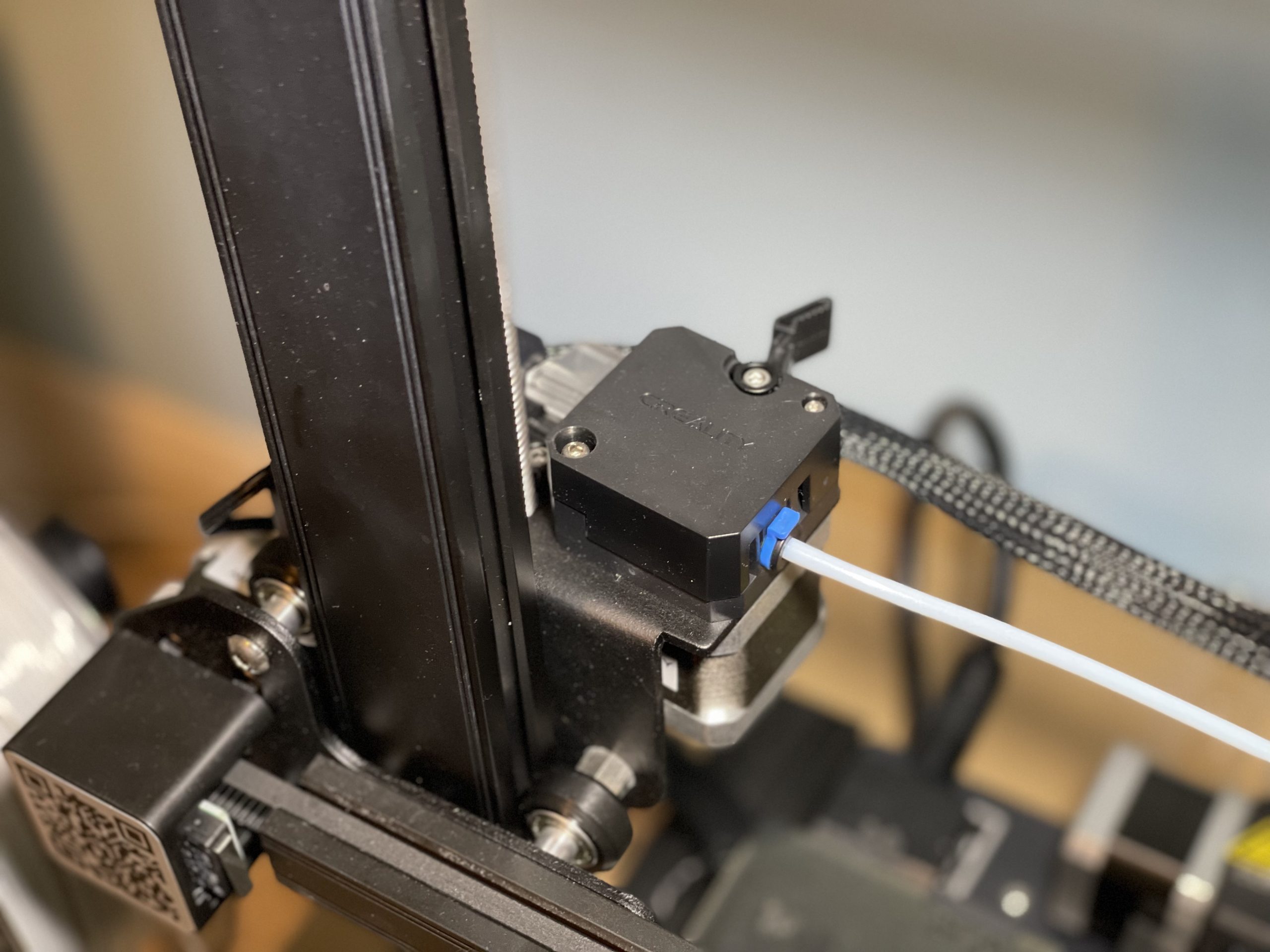

If your 3D printer has a Bowden configuration it means the extruder stepper motor is mounted on the frame of the 3D printer, rather than on the hot end itself.

The extruder pushes filament through a PTFE tube into the hot end. Bowden tube extruders reduce weight from the hot end, allowing for faster print speeds and less ringing. However, they tend to increase stringing and have trouble printing flexible filament.

Reasons to choose a Bowden extruder

The main – and really, only – advantage of the Bowden extruder is the reduced weight on the print head.

Most stepper motors are bulky (they are mostly copper wiring). By moving the stepper motor off of the hot end and mounting it onto the frame, the hot end has much less inertia – making it easier to accelerate and decelerate the hotned.

You should also consider Bowden setups for multi-extruder printers if you plan on only having one hotend assembly.

What are the cons of a Bowden extruder?

The biggest drawback of a Bowen extruder is the amount of distance between the feed gears and the heatbreak/nozzle.

All plastics are elastic to some degree and at faster volumetric feed rates there is considerable resistance generated by plastic (PLA, PETG, ABS, etc) being shoved into the hot nozzle. This is fine when the feed rate is constant. However, every time the nozzle needs to lift or move without laying down plastic a Bowden tube extruder would still be under pressure – causing oozing and stringing.

You can reduce stringing and oozing quite a lot through careful tuning of retraction speeds and retraction distance… but if you’re a beginner to 3D printing it’s a lot of extra work just to get quality prints.

Bowden printers can struggle with printing very fine details that require lots of constant retraction as the large distance feed-retract-feed-retract cycle can start to chew a hole in your filament and cause breakages.

Which 3D printers have Bowden extruders?

Most lower-cost 3D printers use a Bowden tube, such as most Creality printers (most Ender 3 printers, including the Ender 3 Pro, Ender 3 V2; Ender 5; CR-6 SE; Sermoon D1; CR-10; etc.), Tevo Tarantula, and even the Prusa Mini.

Direct Drive Extruders

What’s a direct drive configuration?

In a direct drive extruder setup, the stepper motor is mounted on the hot end itself. The extruder motor pushes the filament directly into the hot end. There is very little room between the extruder and the hot end.

What are the pros of a direct drive configuration?

Direct drive extruders tend to be much better at printing flexible filaments, tend to have less stringing, are easier to configure, and are usually better at printing fine details.

If you’re looking to 3D print miniatures and insist on FDM (vs Resin printers), then direct drive is the way to go.

For configuration, the reduced distance between the stepper motor and the hot end means there is very little compression of the plastic to compensate for when retracting. In other words, you tend to need less retraction speed and distance – allowing for more retractions (often found on detailed models) without causing the filament to strip and break.

Also, due to the reduced distance, the stepper motor has less friction to overcome and doesn’t need to be as powerful. There are now “pancake” motors that are lighter and mitigate the major downside of direct drive extruders (high weight/inertia).

What are the cons of a direct drive extruder?

The added weight from a direct drive extruder may cause some unwanted vibrations in the print head/frame, causing ghosting at high print speeds.

It’s a bit more challenging to configure e steps on direct drive extruders. Also, direct drive extruders can make it harder to reach the hot end and nozzle in case you need to do any maintenance or fixes.

Which 3D printers have direct drive extruders?

The Wanhao Duplicator, Monoprice Maker Select, and Prusa MK3S+ are all examples of printers that have direct drive extruders.

Conclusion: Is a direct drive extruder worth it?

A direct drive extruder is worth it if you’re going to print lots of highly detailed prints that require accurate retraction settings, flexible filaments, or abrasive filaments.

Direct drive extruders are usually more expensive, though. I own a Prusa i3 MK3S+ (a direct drive), several Creality CR-6 SEs (Bowden), and many Ender 3s (mostly pros and a V2). Overall, I’ve found flexible filament to be the major difference for me for when I choose which printer to use.