When it comes to the world of 3D printing, very few brands have a reputation as good as the Czech Republic-based Prusa Research Company.

Originally part of the core RepRap team, the owner and designer Josef Prusa has consistently improved each and every aspect of this unique open-source ecosystem.

From the hardware installed on his 3D printers all the way to the software his machines use, the original Prusa brand is the gold standard for DIY 3D printers.

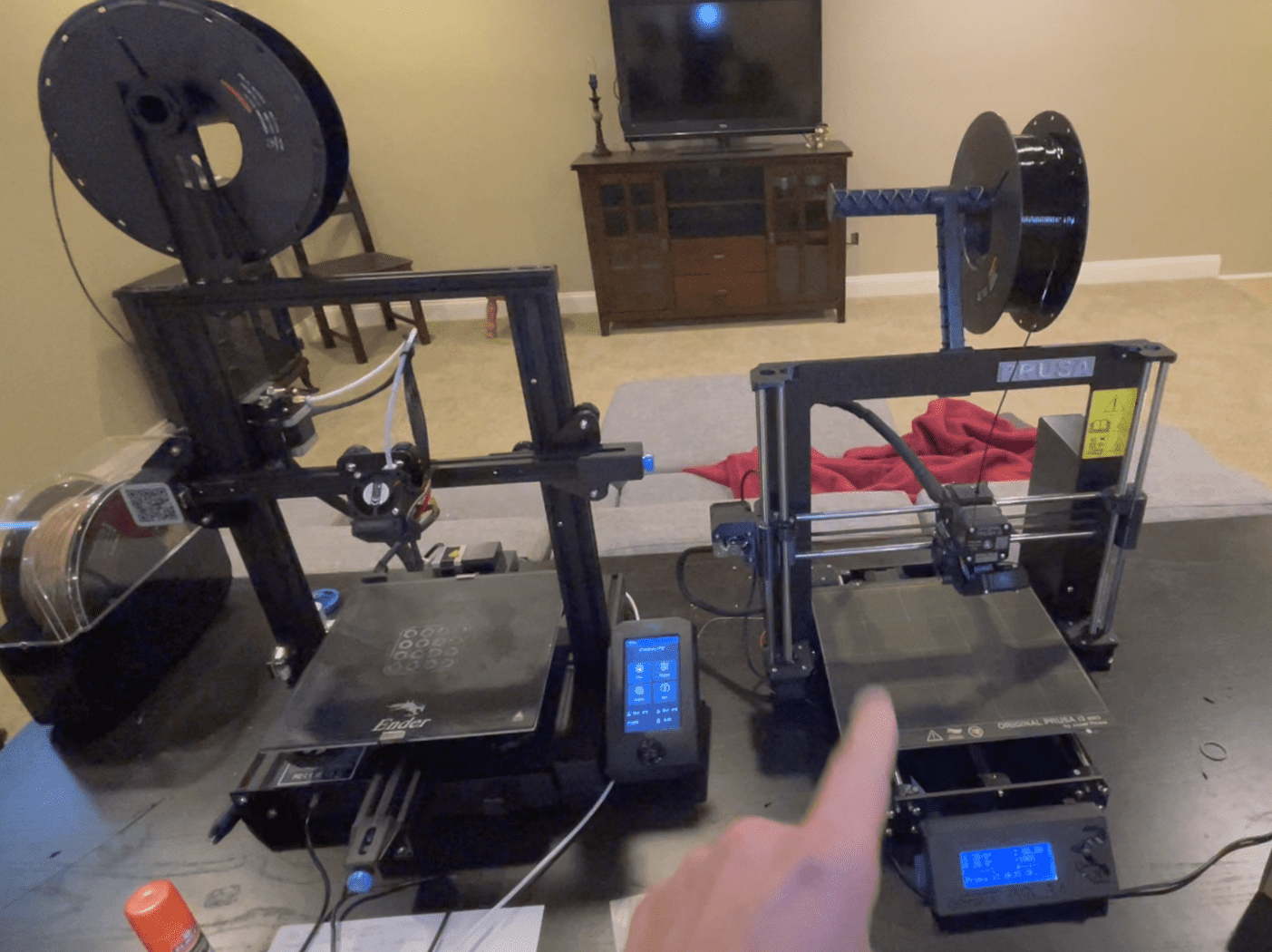

It was the second machine I bought after the Ender 3 v2 and is superior in every way.

Let’s learn more in this Prusa i3 MK3S+ review.

One reason why the 3D printing community loves the Prusa brand is that the company really listens to their community and makes upgrades for the Prusa i3 MK3S+ and other 3D printers only after gathering lots of feedback.

Mr. Josef Prusa and his namesake company have both managed to do something that many 3D printer makers have aspired to do, but have never been successful. And that is to bridge the gap between commercial enterprises and the open-source community.

It is very simple really: Prusa, that is, both the man and the erstwhile printer, do things bit differently. Together, they have made innovation and fine-tuning to be the core of the Prusa i3 series of 3D printers.

In the long run, this means that if you were to invest in any original Prusa i3 3D printer model today, there is a very strong likelihood that your machine would be fully upgradeable in the near future. This holds true not just for the i3 MK3S but just about all Prusa machines.

Prusa i3 MK3S Review: Out of the Box

The Original Prusa i3 MK3S printer is just like its previous iterations in the sense that it is available in a wide selection of formats. You can make it with 3D printable parts and a shopping list (it is open source after all).

Alternately, you can buy it as a kit that you build yourself if you enjoy DIY (do it yourself) work. Finally, you can even get an expert built Prusa 3D printer system that just needs boxing before it is ready to use.

If you are not an expert, it is better to let the real experts handle it and opt for a completely built-up unit (CBU). From the wiring to the insertion of all the relevant components, this is the best option for its price.

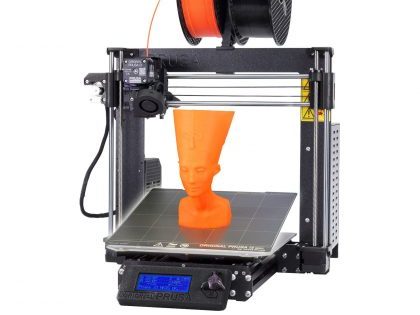

While the Prusa MK3S may be a different beast altogether, it does retain the austere elegance of its former generations of 3D printers.

But here all resemblance ends as this all-new and highly improved Prusa MK3S has been completely refitted and it has been equipped with a completely redesigned extruder system.

This machine includes all of the sum totals of the cumulative upgrades that have been made to this series over the course of time. In this Prusa MK3S review we will help you understand and learn more about this truly exceptional machine. Just keep reading to derive maximum benefit from this comprehensive Prusa i3 MK3s review.

Overview of the Prusa MK3S

In this Prusa i3 MK3S review, we can see that as with its predecessor, this 3D printer Prusa model does not disappoint at all. This is an extremely capable machine that boasts of absolutely stellar print quality.

This is a pretty easy to use and straightforward machine. Yes, this is not a completely different set up when compared to the original Prusa. However, the many significant updates certainly improve the printer’s overall performance, even as they justify its somewhat hefty price tag.

Is Prusa The Best 3D Printer?

In my experience, the Prusa i3 MK3S+ is the best i3 (“bedslinger”) style printer for people who don’t have time to be constantly diagnosing print problems and instead want a printer that “just works”.

Key Features of the Prusa i3 MK3S+ 3D Printer

The Original Prusa i3 MK3S+ looks and feels almost exactly like its predecessor the MK3.

It offers the same 250 x 210 x 200mm build volume and great print quality.

Add to that the sturdy frame that comes complete with it is own iconic orange-colored 3D prints parts.

Apart from that, there are many other staple features such as a cutting edge removable magnetic print bed along with a power recovery system.

In fact, Prusa only recommends buying the kit to upgrade an MK3(s) to the MK3S+ if you plan on using the Multi Materials Upgrade that allows for printing up to 5 colors at the same time.

But if you’re looking to buy your first Prusa MK3S+, let’s dive into why it’s a fantastic idea.

Automatic Mesh Bed Leveling Process

One of the most stressful and frustrating aspects of 3D printing is fiddling around with your manual bed while trying to level it perfectly.

It’s my number #1 complaint about my Ender 3 V2.

Prusa designed the “Super P.I.N.D.A.” sensor that uses inductance to find the high and low spots to create a “mesh”.

Then the printer’s software uses that mesh to be sure the print head is always the same distance from the build plate, regardless of any “hills” or “valleys”.

It’s glorious, simple, and “just works”.

A Completely Redesigned Extruder

This is probably the single most noteworthy change to be implemented into the all-new Prusa i3 MK3S. In fact, many Prusa MK3 users suggested that the unit’s extruder should be easier to access in case anything goes wrong.

This led Prusa Research to modify the extruder design so that the unit’s users would be able to change the nozzle without going through the trouble of taking apart the entire assembly system.

Additionally, the extruder nozzle has been moved closer to the X-axis to reduce resonance and improve print quality.

The new design also has several other refinements such as improved cooling and significantly better Y-axis belt tension.

Optical Filament runout Sensor

On cheaper 3d printers, if your filament spool runs out there is nothing to tell your printer and so it keeps going… but nothing comes out.

Failed print, sad times.

Prusas all have a filament runout sensor (and the mk3s+ has “resume print” – in case of power outages) – helping to reduce failed prints.

With the upgrade from MK3 to MK3S+, Prusa also introduced a fresh new filament sensor.

One that offers greater compatibility with specific filaments.

The company had been experimenting with the mechanical switch mechanism for some time while looking for a new sensor.

This is why Prusa Research decided to combine fresh and new ideas with their old tried and tested ones.

Their old sensor was an infrared, optical only sensor that sometimes failed to sense filament.

The new filament runout sensor is still optical, but is triggered by a mechanical action. From Prusa Research’s website:

Due to some inconsistencies in readings from the optical filament sensor we created the S-upgrade to address this. The new IR filament sensor still uses an optical sensor but is triggered by a mechanical action designed into the new plastic parts of the MK3S, MMU2S, and MK2.5S extruder.

Thanks to this unique hybrid approach, the MK3S+ sensor works fantastically, I’ve never had any issues with mine.

All New Slic3r Software Print Profiles

Apart from all the exceptional hardware-oriented upgrades, Prusa Research has also added multiple new print profiles for both their MK3 and MK3S models. However, here you will have to download Slic3r Prusa Edition 1.41.3 or a newer version in order to access them.

One of the new changes offers a 70μm profile. This is a good option in between the regular 50μm and 100μm profiles. The company is currently marketing it as a great alternative for 3D printing miniatures.

Moreover, Prusa Research has now also packaged its 150μm Optimal and 200μm profiles into different modes including Quality as well as Speed modes, respectively.

As can be imagined Quality mode has been designed for very high surface quality, while the Speed mode substantially increases the overall print speed, without making all that much of a sacrifice in terms of quality.

MK52 Magnetic Heat Bed

The MK52 is a PEI-coated removable magnetic spring steel bed. This is hands down one of the very best heat beds you can find on any budget 3D printer. This nifty little feature makes the whole machine much more usable. Even as the sheet cools down, the various parts can be removed just simply by flexing the sheet steadily inwards.

Power Panic System

The Prusa i3 MK3S is just like its predecessor in the sense that it can also recover and resume a print job, even after a power outage. This is thanks to its EINSY RAMBO motherboard.

This is an intelligent component that can monitor power throughout the system. This allows for the early detection of blown fuses, amongst other issues. Apart from that, it also features Trinamic drivers that are super-fast and very quiet. Furthermore, the power panic system can both detect and rectify the layer shift during the printing process.

How Much does the i3 MKS cost?

At around $1,000, the new and original Prusa i3 MK3S+ is not exactly the least expensive machine on the block.

But boy does it deliver.

Plus, you can save hundreds by buying it as a kit (though you want to seriously consider the choice of mk3s+ kit VS assembled printer due to hidden costs.)

If you are in the market for a sleek and reliable machine; one that creates well-built 3D and beautiful prints and is also easy to use, you won’t have to look much further than this 3D printer.

Prusa is also basically an open-source machine. In other words, it is possible to hack it in a myriad of different ways in order to upgrade it both easily and safely.

Prusa Research also offers an excellent level of tech support and their call center is at hand to take care of any of your issues in real-time. Finally, there is an entire community of highly passionate fans who are both willing and able to offer help or advice whenever and wherever you need it.

Prusa’s Software Slicer – a match made in heaven

The Prusa slicer that comes bundled with the mk3s/+ is fantastic and easy to use.

It has a very simple and intuitive design and is very clear and easy to use. However, the simplicity does not mean it lacks features. This is a very powerful software tool that offers heaps of customizations and settings.

One of the best aspects of Prusa’s software slicer is its instinctive operating system (OS). Even a newbie to the 3D print world would be able to pick it up and start using it very quickly indeed.

It comes with a variety of preconfigured settings that include some of the most common filaments that are used by Prusa’s current 3D printer lineup. Unlike Cura and many other ‘one size fits all’ commercially available 3D slicers out there, this is more of a bespoke tool. One that has been tailor-made for your new original Prusa i3 machine.

Prusa i3 mk3s+ Technical Specs

In spite of the many advanced features of the Prusa i3 MK3S machine, the technical specifications are largely the same as in previous iterations.

Let us take a quick look at its technical specifications sheet (I’ll bold important/extra useful items):

Main Printer Specs

- Manufacturer: Prusa Research

- Print Bed: Heated bed, Removable Magnetic PEI Coated Spring Steel build plate

- Build Volume: 250 x 210 x 200 mm

- Max. Extruder Temperature: 300ºC

- Max. Print Bed Temperature: 120ºC

- Extruder: Direct Drive

- Filament Diameter: 1.75 mm

- Can use Third-Party Filament: Yes

- Easy Octoprint integration

- Connectivity: USB and SD Card

- Onboard Controls: Yes

- Weight: 6.35 kg in total

Software Specs

- Host or Slicer Software: PrusaSlicer

- Firmware: Marlin

- OS: Mac, Windows, Linux

- Open Software/Hardware: Yes (GNU GPLv3)

Pros

- Set it and forget it – you hit print, it prints, no fuss

- Exceptional print quality

- Print pause and restart

- Crash detection

- Filament runout detection

- Prusa’s Slic3r-based slicing software is very user friendly

- Very sturdily built

- Enthusiastic and helpful community (KEY for fixing any issues… if you ever have them)

- Auto-calibration and bed leveling

- Beautiful bridging and overhangs

- Prusa support responds quickly and their call center agents are very knowledgeable

- Extensive community support

Cons

- It’s a serious pain to build from the kit

- It’s somewhat expensive (VS building your own from scratch).

The best thing about the Original Prusa i3 MK3S+ model is that it just plain works.

I have literally never had to fuss with my printer, no calibrations, no disassembly to debug some issue… nothing.

Prusa Slicer is very easy to use and comes with great default print settings.

The prints pop off with near ridiculous ease due to it the magnetic PEI coated spring steel plate.

Due to the direct drive extruder, it prints PETG, TPU (flexible filaments), PLA/PLA+… really anything that doesn’t need a heated chamber.

It’s a rock-solid printer that will consistently give very good results for a very long time.

What are the Major Differences between Prusa Mk3 and MK3S?

In many ways, the Original Prusa i3 MK3 is very like its newer and flashier counterpart. However, these two are very different printers in their own right. Some of the major differences include the following ones:

Firmware Support

The MK3 uses its own B7/R3 extruder design to compete with its own optical filament sensor. This means that it will run on its own MK3 firmware. The i3 MK3S on the other hand uses a vastly different extruder design bundled with a brand new IR sensor. This means that the machine won’t run on the older version’s firmware. On the contrary, it would require a completely different MK3S firmware application.

Redesigned Filament Extruder

This is the key difference between the Original Prusa i3 MK3S and its newer i3 MK3S counterpart. The i3 MKS extruder has been well equipped with a cutting edge hybrid system that comes with both an optical filament sensor as well as a standard mechanical lever.

Apart from the overall improvement in quality and speed, it is now also possible to change both the nozzle and if required; the PTFE tube. However, here it is pertinent to note that the total build volume still remains very similar to the previous i3 version since the size is the same for both these Prusa printers. However, this should be more than adequate for most prints as such.

Sensing Fans and Noctua

These upgrades can help to substantially reduce the noise when the i3 is printing any 3D object. Apart from that, a cooling breeze that emanates from both sides of the extruder will substantially increase the original Prusa i3 MK3S printer’s overhang performance.

Bondtech Extruder

Its dual gears ensure a very reliable and safe grip on the printing filament to prevent any slipping related accidents. The extruder’s nozzle can easily reach up to 300°C.

Y-Axis Belt Tightener and other Upgrades

Apart from the Y-Axis belt tightener, the MK3S has also been equipped with genuine Gates belts to ensure a smoother flow of the whole of the work process. And that is not all; the good people at Prusa Research have also replaced the standard spiral wraps with textile sleeves.

They have also created a new Einsy case and added an anti-rust coating on the otherwise smooth PEI sheets of the hot bed. Apart from that, there are many firmware as well as plastic parts enhancements too.

Verdict: Is the Prusa MK3S worth it?

In short, we can say that this Prusa printer has few peers and hardly any superiors.

If you want easy printing and outstanding quality just get this machine today.