The strength of a 3D printed part depends on many factors: the type of filament material you use, the shell thickness, the layer height, and of course, the infill.

So what’s the strongest infill pattern? Let’s dig a little deeper.

What’s the strongest infill pattern?

Under most circumstances, the strongest infill pattern is the honeycomb pattern. The hexagonal shape lends strength from all directions to the honeycomb pattern, and it is modeled after the natural honeycomb structure of beehives.

When you stack hexagons together as in a honeycomb, it lends a lot of compression strength from all 6 walls.

The honeycomb infill pattern is also very material-efficient as it requires much less filament to print than other infill patterns.

Overall, the honeycomb pattern has the best strength-to-weight ratio and for this reason, many applications that require very light objects(like aerospace) utilize honeycomb patterns.

However, FDM printers take a long time to print this infill pattern as there is a lot of print head movement.

A triangle infill or rectilinear infill would just require straight lines, whereas the hexagon infill requires more movement by comparison.

What about infill percentage?

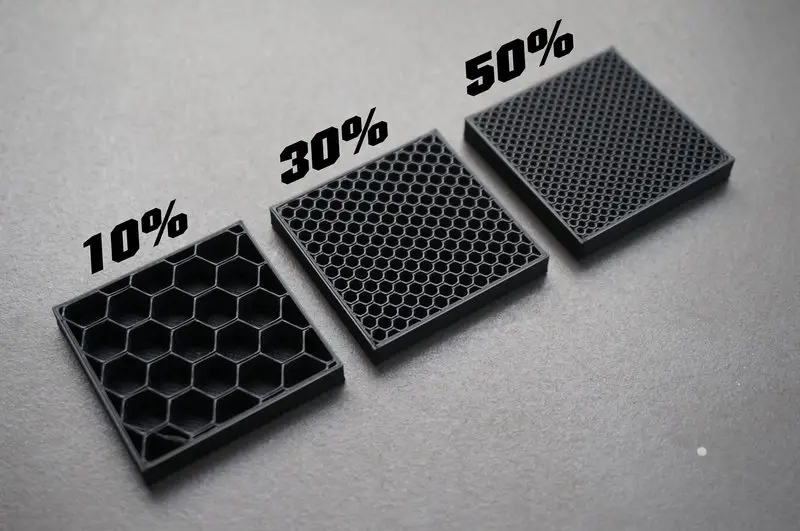

Infill percentage is a bit contentious. Usually, you can get away with less infill percentage for everyday use.

There will rarely be an occasion where you’ll need more than 50% infill percentage, and for most parts, 20% or so infill percentages will suffice, especially if you use a strong pattern like the honeycomb.

For models that will come under a lot of stress and require lots of part strength, you may need higher infills.

Drone parts, for example, may even require 100% infill density as they will come under lots of impact.

Source: Triplaxis

Recommended infill density for various models:

- Display models: 10%

- Brackets and functional models: 30-40%

- High-stress parts like drone components: 60% or greater

What other infill patterns are strong?

Other very common infill patterns are triangle, rectilinear, and gyroid.

Triangle and rectilinear

Triangle and rectilinear infill is quite standard and is actually preferred for most printing as it is both strong and quick to print since it is just a lot of straight lines.

The cross-section of this pattern would just look like a simple grid.

However, where the honeycomb structure is strong in all directions, the triangle and rectilinear patterns are strong in one direction, but opposite in the other.

So if vertical force was applied, the print would hold up very well, as each layer is very well-reinforced by the other layer.

But if you were to apply a horizontal force to the object, especially at a weak point, this infill would not hold up very well.

Gyroid

Gyroid infill is a newer infill pattern and has the 3D printing world quite abuzz due to its efficiency and strength.

Gyroid infill is quite complicated, as it’s actually straight lines printed at very fine angles to one another to form a curved pattern.

Because of the similarity to the honeycomb structure, gyroid infill is quite strong in all directions and prevents the object from shearing.

Your prints will come out a little faster with gyroid infill than they would with honeycomb, as the straighter lines lend to slightly faster printing times.

However, gyroid infill requires giving your 3D printer a lot of complex instructions, and the slicing time will increase greatly as a lot more processing power is required to generate the .gcode file.

Another issue with gyroid infill is that older printers running dated hardware may not be able to handle this infill structure very well, and you may find that your prints fail more often!

Also, not all slicer programs are able to handle gyroid infill. As far as I’m aware, Cura is able to slice with gyroid infill.

Other factors that affect print strength

Aside from infill patterns, the other factors that affect the strength of your 3D printing projects include:

Filament type and quality

The type of filament you use plays a huge part in whether your 3D printed part comes out strong or weak.

PLA is a great overall filament but it is not very strong and is not suitable to use for a part that will come under a lot of stress.

ABS is a very strong filament but it is very difficult to print, and the printing process gives off toxic fumes which must be filtered out using a fume hood.

PETG is very strong and combines the best of PLA and ABS, and is actually ideal for many projects that PLA is not suitable for.

Filament quality will also make a huge difference in the print even across the same type of filament.

A PLA part printed with the same settings but with high quality PLA will be much stronger than a part printed with a cheaper filament or filament that has absorbed moisture.

Shell thickness

Shell thickness is also very critical for print strength, perhaps even more so than the infill percentage!

The shell determines the outside strength of your print, so even if you had a very strong infill, if you used a low shell count, the outside of the print will still be quite weak.

Part strength depends on both a strong outer shell and a good infill.

Use at least 3 shells if your layer height is 0.2mm: aim for at least 0.6mm thickness. This means if you use a smaller layer height, you’ll need to adjust the number of shells to maintain a good thickness!

Print orientation

The print orientation is another very important factor as the layer lines determine fracture points.

A good example is to think of an L bracket.

You can print an L bracket by laying the bottom of the L flat on the print bed, and printing upwards so the top of the L will be a tall tower.

With this orientation, the tower will be quite weak as there are lots of layer lines and they’re pretty small!

A better way to orient this print would be to lay it on it’s side, so that the bottom and top of the L print at the same time.

In this orientation, the bottom and top of the L both have very long layer lines, and the layer lines will end up perpendicular to the direction of the force on the bracket when you finally mount it.

This will actually lend even more strength to your print than any amount of infill percentage!

Top and bottom layers

Finally, the top and bottom layers also influence the strength of your print. The bottom layer is the footprint of your model, and a strong bottom layer will result in a successful print.

Try to use at least 3 bottom layers for 0.6mm of thickness(adjust according to layer height), and do the same for the top layer.

The top layer is a seal for your model, so it’s essential for both aesthetic reasons and part strength that there are enough top layers.

Visualizing types of infill

There are a few really awesome YouTubers who post timelapses of their 3D prints which let you visualize the infill types very nicely:

Related

Conclusion

3D printing is all about experimentation and having fun, so I recommend that you print a handful of calibration cubes using a variety of infills and percentages and see what kind of results you get.

For parts that need strength, stick to the honeycomb or rectangle patterns as they’re the best in terms of print quality, overall strength, and material efficiency.