The Ender 3’s stock nozzle is a 0.4mm brass nozzle with an M6 thread. It conforms to MK8 hot ends, which are the standard for most home 3D printers thanks to the wide adoption and easy availability of parts and spares.

The Ender 3 is one of the most popular 3D printers on the market and for good reason. It’s easy on the wallet, can print a wide variety of materials out of the box, and has a really robust hot end that can handle decent print speeds.

Out of the box the Ender 3 printers (including the Ender 3 Pro and Ender 3 V2) come with a 0.4mm nozzle. Think of this as the goldilocks nozzle size – small enough to give great detail but large enough that it doesn’t take forever to print something.

But how can you get the most out of a 0.4mm nozzle? Good question, read on…

Ender 3 Nozzle Material

The Ender 3’s nozzle is made of brass, which is a really good material for everyday prints. Brass is cheap, easy to shape, conducts heat very well, and does not corrode or oxidize easily, making it a super choice for high-heat applications.

If you remember your chemistry, heat and oxygen always do a number on metals, so you need your nozzle to stay chemically unchanged even after prolonged exposure to heat and oxygen.

The only drawback of brass is that it is relatively soft(as far as metals go), so certain abrasive filaments can slowly damage it over time. However, for most hobbyists who print basic materials like PLA, ABS, PETG, and TPU, the brass nozzle will work like a champ and you won’t need to look anywhere else.

What you can print with a 0.4mm nozzle

There’s a good reason that 0.4mm nozzles are the standard for most home 3D printers including the Ender 3. This size falls under the “Goldilocks zone” that can handle both high-resolution prints as low as 0.12 mm and faster prints like 0.32mm.

0.12mm and 0.32mm are what I would consider the extremes for printing with the stock Ender 3 nozzle. Anything lower than 0.12mm will not extrude enough plastic and your model will end up with lots of holes and incomplete layers.

Anything higher than 0.32mm and the nozzle will probably get jammed trying to extrude so much plastic.

For most 3D prints, you won’t need a resolution smaller than 0.o8mm or greater than 0.32mm. My prints are mostly 0.2mm unless I need to 3D print something super fast or in super-high resolution.

3D Printing with larger nozzles

Using a large nozzle has its applications. There are times where you may wish to print something with larger layers.

Larger layers will usually result in stronger prints, but the prints will not look quite as visually appealing as a print with smaller layers.

One of the biggest advantages of printing with large nozzles is the increased print speed. However, a larger nozzle does not always equal a larger print speed.

If you use a nozzle larger than the stock 0.4mm one, like a 0.6, 0.8, or even 1.0mm nozzle, one thing you need to be mindful of is the amount of heat your hot end can generate.

The larger your nozzle is, the more efficient your hot end has to be in order to keep melting the plastic that’s being fed through. So you may find that in order to keep the plastic flowing, you will have to reduce the print speed.

One workaround is to upgrade the entire hot end to an all-metal hot end from a company like E3D. All metal hot ends have larger heating elements, so they’ll be able to supply more continuous heat to keep the plastic flowing.

However, the moment you increase your layer size, the model will definitely print faster, since there are fewer layers to put down. A model sliced with a 0.4mm layer size will print in around half the time it takes for a model sliced with a 0.2mm layer size.

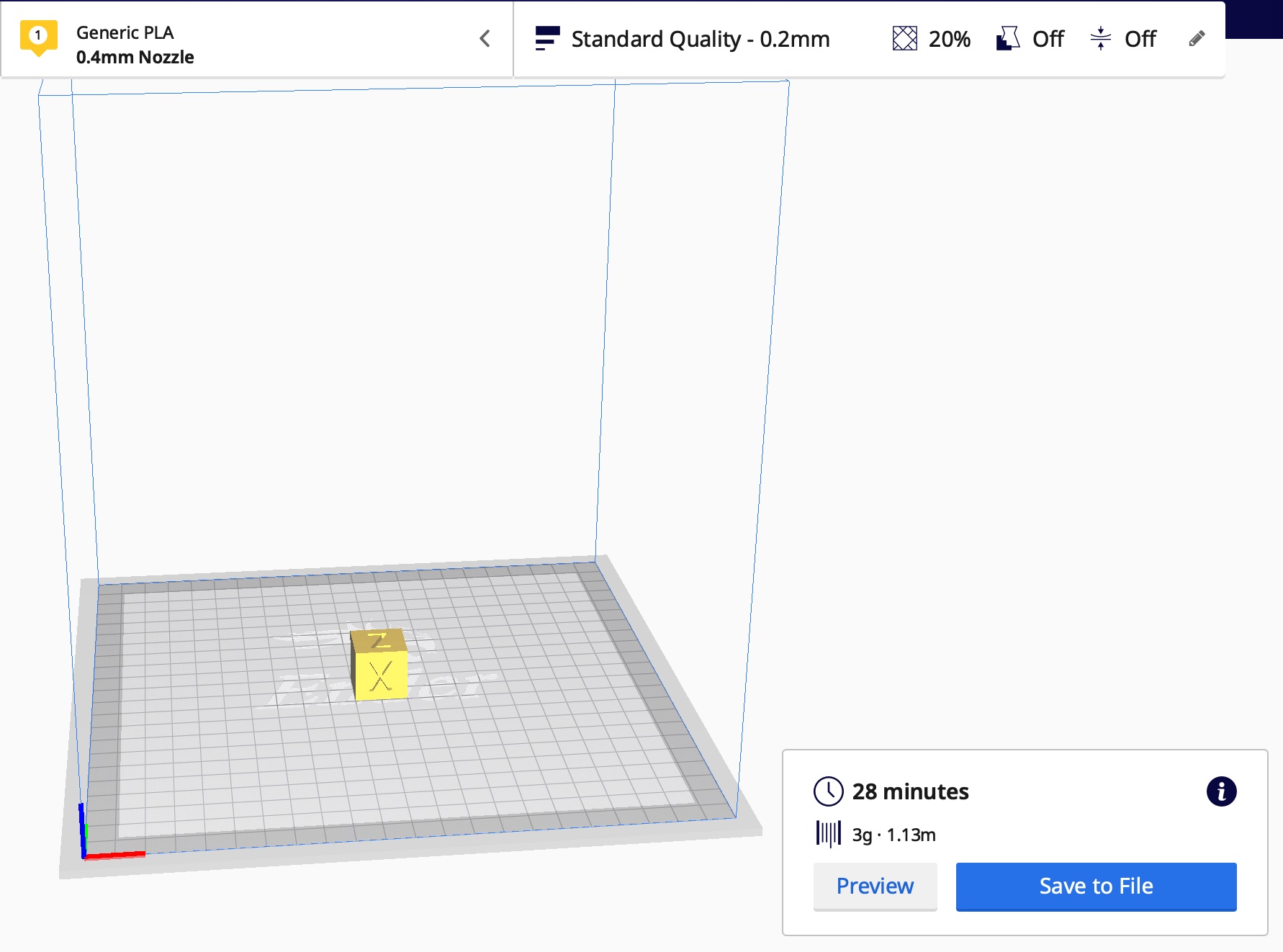

Here is a screenshot from Cura with a 0.4mm nozzle and 0.2mm layer size:

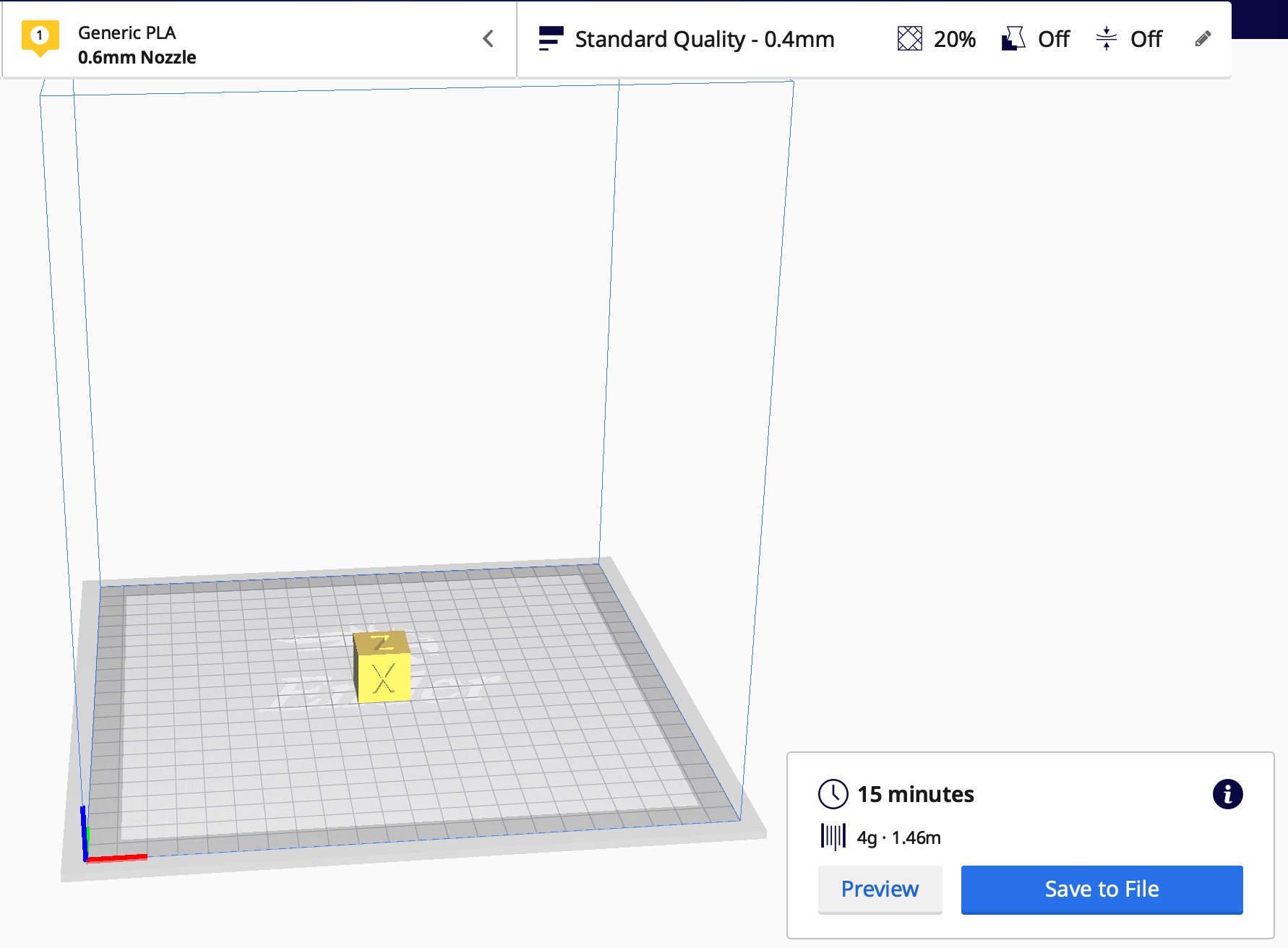

The screenshot below is using a 0.6mm nozzle and a 0.4mm layer height:

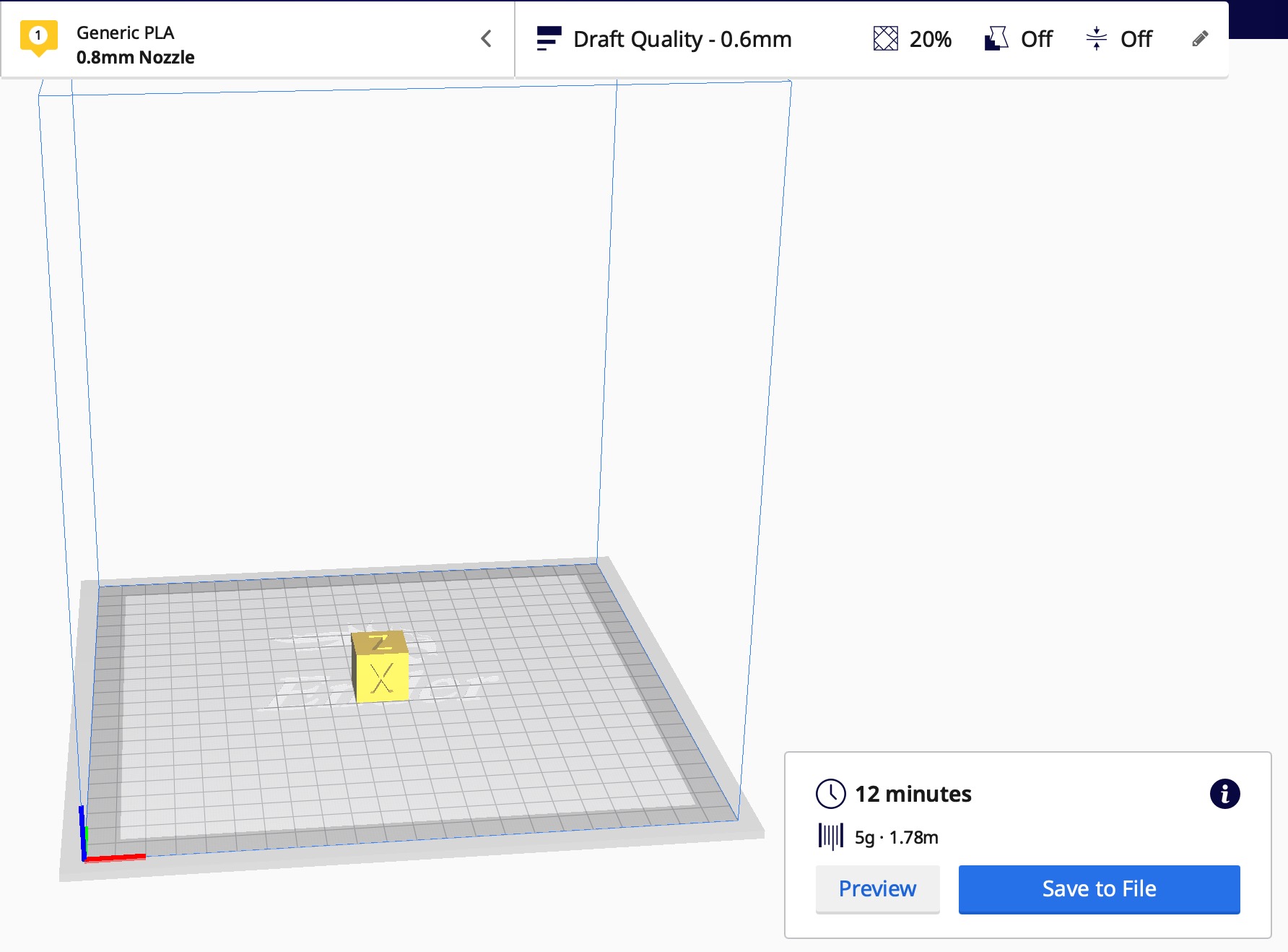

To make things interesting, we can try increasing the layer height even more and decreasing the print speed to see what kind of a difference that makes.

Now at a layer height of 0.6mm with a 0.8mm nozzle and a print speed lowered from 50 mm/s to 30 mm/s, the 3D print still completes faster:

So if you’re looking for faster print times, a larger nozzle is definitely the way to go.

The only drawback of the larger layer height is that the model will not be quite as visually appealing as a model with smaller layers. All FDM 3D prints have visible layer lines, and using larger layer heights will make those lines even more obvious and in-your-face.

3D printing with smaller nozzles

The smaller your Ender 3’s nozzle is, the greater resolution you’ll be able to get out of your printer. Higher resolution prints look much more visually appealing as the layers lines become less and less visible the smaller the layer height is.

If you want something with a good finish, small layer heights will help you get the best an FDM printer is capable of.

Additionally, smaller layer heights are good for printing models that have very fine details. I once tried to print a model of the Eiffel tower that had very thin beams and my stock hot end just could not print them. They’d end up turning out as wisps, probably because the hot end was not able to process the .gcode file’s instructions.

A smaller nozzle and layer height means those tiny details will actually show up in your print.

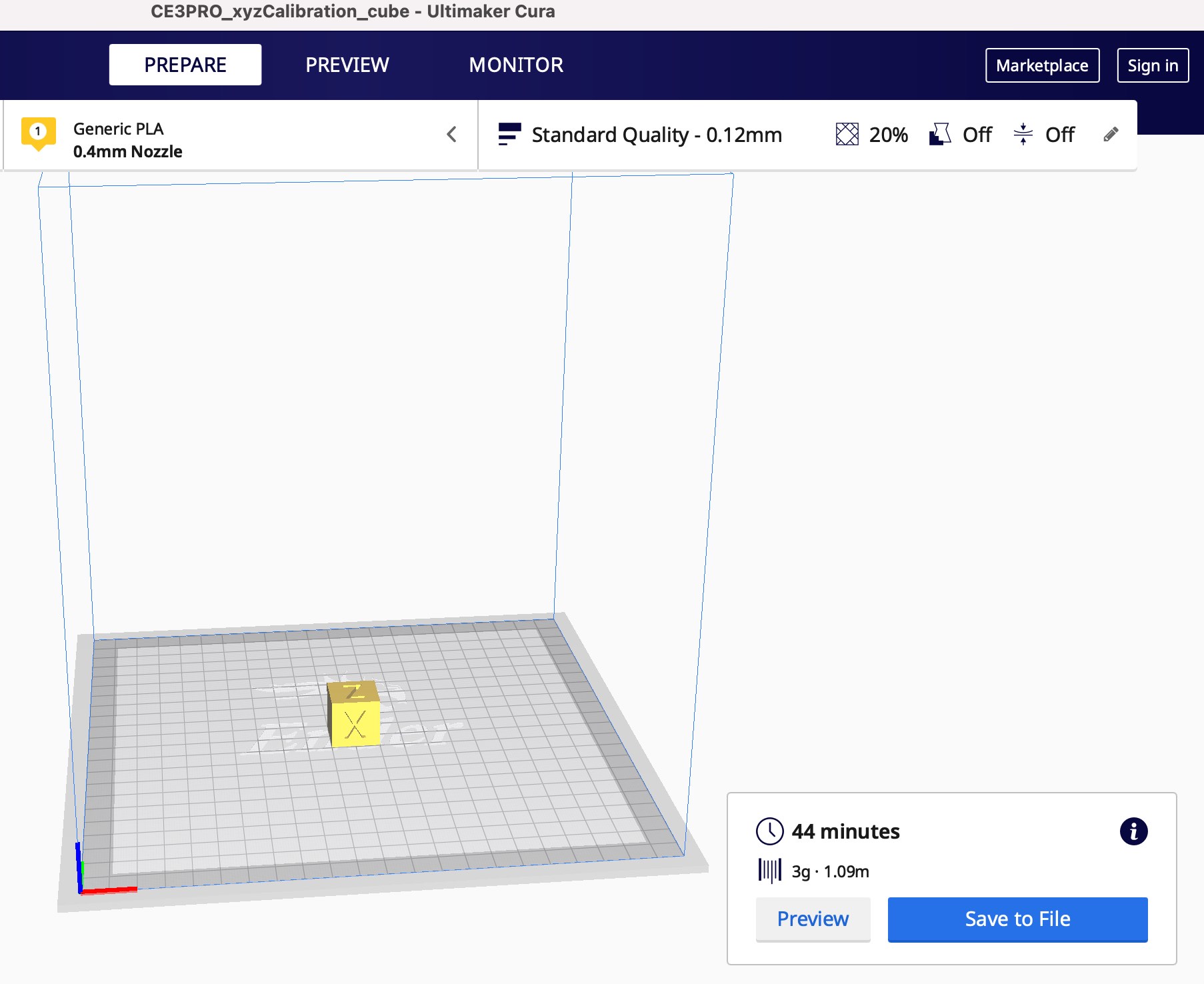

However, the main drawback of smaller layer heights are the extremely long print times. 3D printers are pretty slow by nature anyway, and using higher resolutions will make the prints even slower.

Yikes!

Here’s an example of a calibration cube sliced with a 0.4mm nozzle and a 0.12mm layer height at 50 mm/s:

Finally, one often-overlooked disadvantage of very small nozzles is the increased likelihood of clogs and jams. Even the smallest speck of dust can cause things to go haywire.

To fix this issue, you’ll need to make sure you use the highest quality PLA and even consider printing a filament cleaner that wipes the filament clean before feeding it into the extruder.

At this point, you should really consider if the smaller nozzle can really get you the results that you want. For example, if you are into printing highly detailed miniatures, thFien it may be worth getting an SLA printer instead.

Upgrading the Ender 3 Nozzle For Exotic Materials

Finally, you may wish to upgrade the Ender 3 nozzle from a brass nozzle to one of a different material so you can easily print exotic materials.

You may not wish to print abrasive filaments, but if you want to print higher-temperature filaments, a nozzle made from a harder material will be useful.

Some nozzle materials you can consider for high-temperature or abrasive filaments like carbon fiber or metal-fill are:

- Stainless steel

- Carbon steel

- A2 tool steel

- Copper with sapphire ruby

- Nozzle X

It’s important to note that just using a different nozzle material may not be enough: for some filaments, you will need to upgrade your entire hot end to be able to keep up with the required heating.

- Premium Quality--MK8 nozzles are made of high quality brass material.Heavy duty and provide a long service life.Easy to install and change.

- Precise Design--3d printer nozzles can prevent print head from leakage effectively and produce consistent prints with smooth and glossy polish.Reduce the resistance from the corners and avoid blocking...

- Applicability and Compatibility--MK8 extruder nozzles fit for 3D Printer Makerbot Creality CR-10, MK8 Makerbot Reprap Prusa I3, compatible with all 1.75mm PLA ABS 3D printer. Fit exactly like the...

- Package Include--Printer nozzles come with 24 pieces MK8 nozzles in 7 sizes(quantity x output diameter): 2 x 0.2mm, 2 x 0.3mm, 12 x 0.4mm, 2 x 0.5mm, 2 x 0.6mm, 2 x 0.8mm, 2 x 1.0mm,with a plastic box...

Related

Conclusion

The Ender 3’s stock nozzle size of 0.4mm is more than enough for most hobbyists, but if you ever want to level up your 3D printing and print faster, smaller, or with more exotic materials, you should consider another nozzle from the ones mentioned here.

A nozzle upgrade will probably not be the first one your list, but it’s definitely something you can consider in the long run. This is what makes the Ender 3 such a great 3D printer: it really grows with you and you can gradually add or upgrade whatever parts you need according your requirements.