Looking for the best 3D printer hot end? You’ve come to the right place. We’ve chosen the 5 best hot ends that you can buy for your 3D printer and listed them here.

The most important part of your 3D printer is the hot end. The hot end is what delivers the filament. A good hot end enables you to produce consistent prints and lets you work with a wide variety of materials.

In this post, we’ll take a look at the 5 best hot ends currently on the market. We’ll also share what each hot end is good for, and why we chose this hot end over any other models.

The Best 3D Printer Hot Ends at a Glance

Why you need a good hot end

- A high quality hot end can deliver accurately-sized strands of filament

- It can reduce the chances of a print failing

- It can help increase your print speed

- It can let you 3D print more materials

- It can hold temperature better, resulting in consistent 3D prints

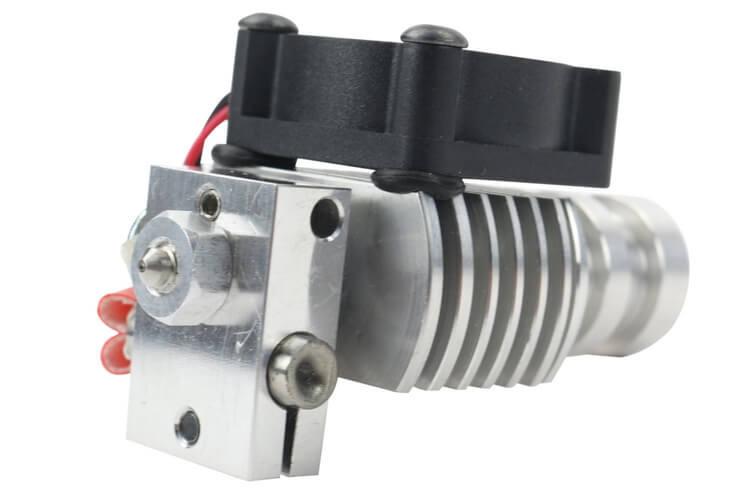

1. E3D V6 All Metal Hot End: Best Overall

The E3D V6 is the undisputed king of all consumer-grade hot ends.

For super-accurate prints and working with high-temperature filaments, the E3D V6 all-metal hot end is incredibly reliable and functional. This hot end is used all over the world on many different kinds of machines, and chances are you’ll be able to find a mod for your printer that lets you work with the E3D too.

The E3D is so popular that it’s also one of the most heavily-cloned hot ends on the market, too. That’s why you need to be very careful when searching for it on large marketplaces, or you may find yourself with a clone instead of the real thing.

The E3D V6 is actually a whole group of hot ends that have varying nozzle sizes, materials, as well as Bowden and direct-drive setups.

That’s what makes the E3D a really good pick for pretty much anyone looking to upgrade their hot end. It’s a no-brainer and will almost certainly fit your 3D printer.

The all-metal hot end can work with Nylon and other high-temperature filaments. If you’re just looking for reliability and consistiency without the need for high temperature printing, you can go for the E3D V6 lite, which is almost the same except it has PTFE-lined parts on the inside.

This means you can’t go higher than 230 degrees C, as that will deform the PTFE.

The E3D nozzle typically comes unassembled but you can opt to get an assembled version too.

A simple search on Thingiverse will yield mods for nearly every popular 3D printer to fit the E3D.

The E3D works with 1.75mm filaments

Why we like the E3D:

- Highly reliable

- Lightweight

- Compatible with hundreds of 3D printers

- Budget-friendly

2. E3D Hemera

The next hot end on our list is the E3D Hemera.

The Hemera is a unique direct-drive hot end that is a fully contained unit with both the hot end and the extruder. Both components are assembled neatly in a very compact form factor.

The motor mounts also serve as part of the extruder, helping make the Hemera a very compact hot end. Because the design is so tiny, there is very little room between where the filament moves through the extruder gears and where it goes into the hot end.

This greatly reduces the chances of failure between these two points, so the Hemera is a superb choice if you work a lot with flexible filaments.

Another unique design feature of the E3D Hemera is the heatsink. The way the heatsink is positioned enables it to blow hot air away from the print bed. This is huge, considering that any unwanted hot air going towards the build plate will affect the cooling of your model as it prints.

The Hemera follows suit of other E3D products that are highly moddable and fit most 3D printers with ease. You can even convert the Hemera into a Bowden system if you need to.

You can also find printable mounts on the E3D website.

The Hemera works with 1.75 mm filaments

Why we like the Hemera

- Very lightweight

- Well-thought-out design

- Good for flexible filaments

3. Diabase Flexion Extruder

Another hot end that’s ideal for printing with flexible filaments is the Diabase Flexion Extruder/hot end. If you’re printing flexible filaments on a commercial scale, the Diabase is a good choice because you can print faster with less chances for errors.

The feeding mechanism was designed with flexible materials in mind, as it grips the filament with greater strength and forces it into the hot end. This reduces the chances of the filament noodling out or jamming up in the hot end.

This mechanism is further aided by a wire brush that constantly cleans the feeder gear teeth to make sure the grip remains tight. All this put together lets you print up to 70 mm/s with flexible filaments as claimed by the manufacturer.

Realistically, you’re looking at speeds of 40 to 50 mm/s, which is still a huge jump over the 10-15 mm/s speeds you have to use on cheaper extruders and hot ends.

The assembly is compatible with E3D-style mounts, so that makes installation a breeze.

The Diabase Flexion is available as a dual and single extruder kit and works with 1.75mm filaments.

Why we like the Flexion:

- High-speed flexible prints

- Compatible with a lot of different 3D printers

4. Slice Engineering Mosquito Hotend

The Slice Engineering Mosquito is a really unique take on hot end design that breaks the mold of a typical hot end design. In fact, you may not even recognize it as a hot end the first time you see it!

A typical hot end is a heat sink that’s connected to a heater block. The Mosquito holds everything around a metal frame, which lets you use a smaller copper heatsink that’s more efficient than aluminum heatsinks.

A more efficient heatsink reduces the chances of heat creep, which can cause jams and poor prints.

The heater block is connected directly to your 3D printer’s frame and can mount very easily onto any 3D printer.

You can use Slice Engineering’s own nozzles or even E3D nozzles on this hot end.

Why we like the Mosquito:

- Groundbreaking design

- Efficient heating

- Very lightweight

5. DisTech Prometheus V2

Last but not least, we have the DisTech Prometheus V2 hot end. Made from a single piece of stainless steel, this all-metal hot end allows for very smooth and error-free 3D prints.

The active cooling mechanism enables to filament to melt very consistently and flow without any hindrances.

Because it’s machined from a single block of stainless steel, it’s much stronger than other hot ends that have brass parts. Brass is a comparatively softer metal.

The heat sink is flat as opposed to the E3D’s round heatsink. This lets you mount it much more easily to any 3D printer.

The Prometheus V2 works with 1.75mm filaments.

Why we like the Prometheus V2

- Very strong and wear-resistant

- Great heat transfer

Related

How to choose a hot end for your 3D printer

Now that we’ve looked at the best 3D printer hot ends, how do you decide which hot end is right for you?

Here are some questions to ask yourself before deciding:

What materials are you going to print?

Indeed, the question of materials will be the main deciding factor for which hot end you choose. To print with high-temperature filaments like nylon, you’ll need an all-metal hot end that can handle such high temperatures. The E3D V6 and Prometheus V2 are good picks in this case.

For flexible filaments, consider the E3D Hemera or the Diabase Flexion, as these two are built with flexible materials in mind.

If you’re just looking to upgrade the stock extruder on your budget printer and don’t plan on printing flexible or high-temperature filaments then the E3D lite is a budget pick that can improve your print quality right away.

What is your budget?

The budget question is the second big question to ask yourself. How much are you willing to invest? In some cases, the hot ends we’ve listed here cost almost as much as a new 3D printer!

However, this is not a bad thing as starting out with a budget printer and gradually upgrading it with higher-end parts is a great way to ease yourself into the hobby.

If you’re only going to print PLA, you can get away with the E3D lite and nothing more. But the moment you want to concentrate on exotic filaments, you’ll need to use a higher quality hot end.

What model 3D printer you have

The hot ends we’ve listed here are nearly universally compatible with all models of 3D printers. As long as your 3D printer is a commonly available model(or based off a commonly available model), you should be able to find and print mounts for it.

The only exception is the Prometheus, which does not have as much of a community following as the other hot ends we’ve listed here.

If you’re not sure, you can’t go wrong with e3D hot ends as they can fit almost anything.

Understanding 3D printer hot ends

Many hot ends come unassembled, so it’s useful to know the different parts of a hot end:

- Nozzle: This is where filament flows out from onto the print bed. The smaller the nozzle, the more precision you can get in your prints. However, smaller nozzles lead to longer print times.

- Heat block: This is a metal piece that generates the heat to melt the filament. It is connected to a thermistor, which helps the main board regulate the temperature.

- Thermistor: This is a small device that gives temperature feedback to the main board.

- Heat break: This is a small metal tube that connects the heat block to the heat sink. The filament moves through the heat break into the heat block to melt.

- Heat sink: The heat sink helps dissipate heat from the heating element with the help of a fan.

Conclusion

These are the best 3D printing nozzles that money can buy. They fit most 3D printers, and cover most of the applications required by hobbyists and professionals alike.