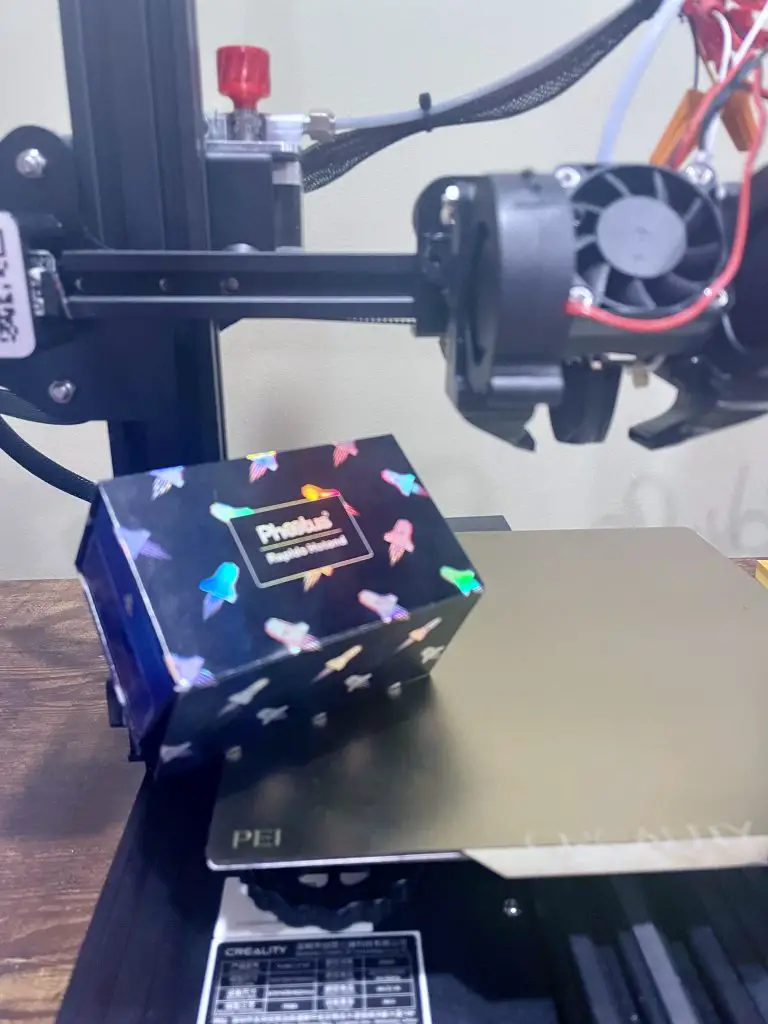

I have two 3D printers: a Prusa i3 MK3S+ (the workhorse) and an Ender 3 V2 (my fidget printer).

Lately, I’ve been working on “Project Hurricane”, turning my Ender 3 V2 into a 1000 mm/s speed deamon printing at flow rates pushing 50 mm^3/s.

The first major upgrade to get there… a high flow hotend. Or in the case of the Phaetus Rapido an “are you kidding me” flow hotend.

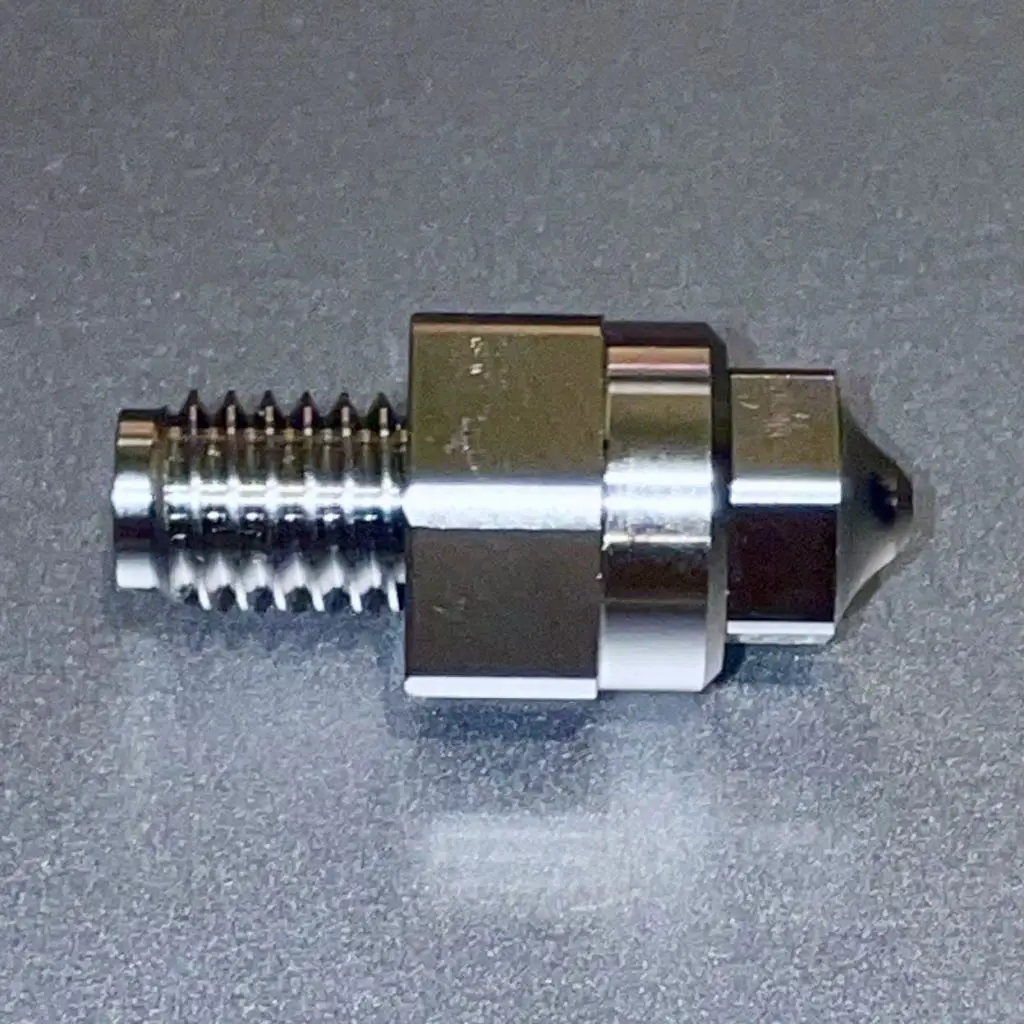

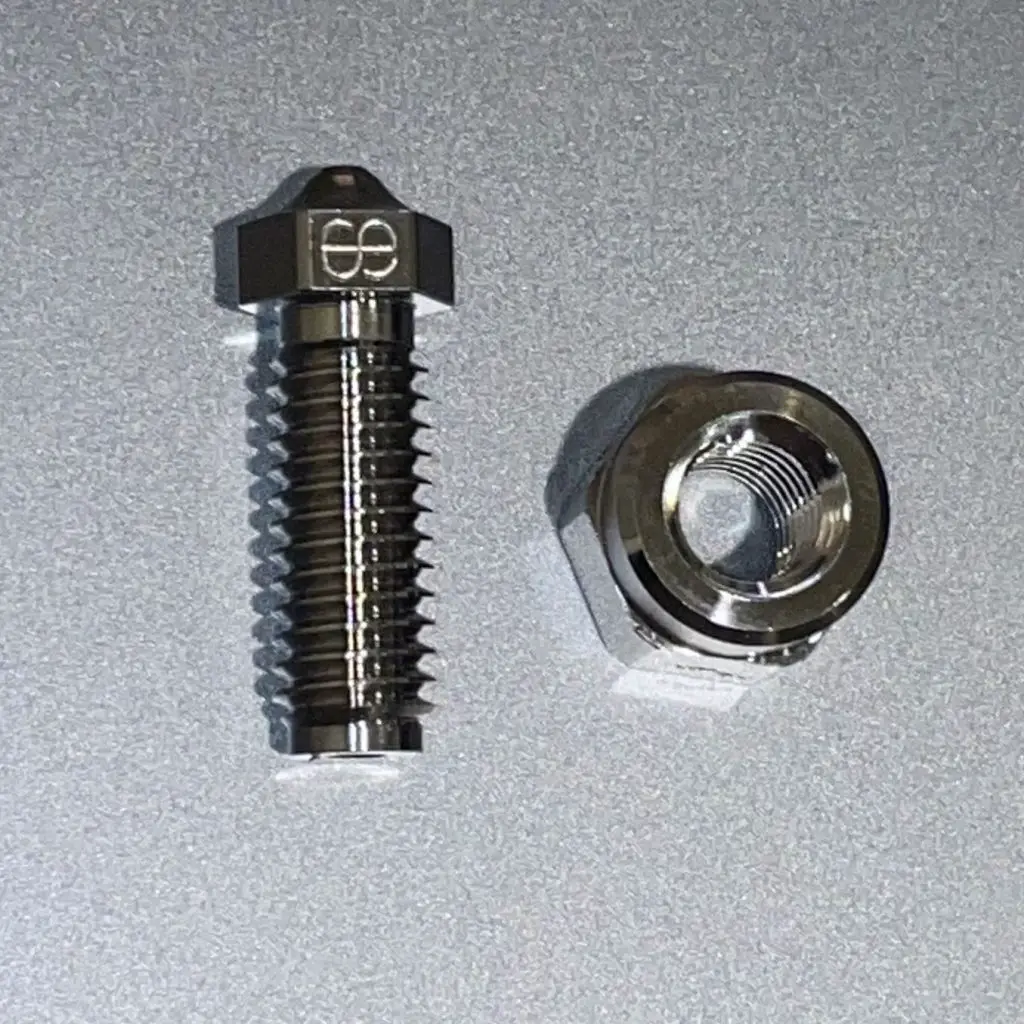

One thing I like about the Ultra High flow design is this E3D Volcano length nozzle. To account for the extra length they include a nut/sleeve to help maintain some thermal mass. It’s clever.

- 【New heating block design】:The new design of the heating block has a larger melting zone to meet the requirements of high-speed and high-temperature printing. Use Standard V6 type Nozzle

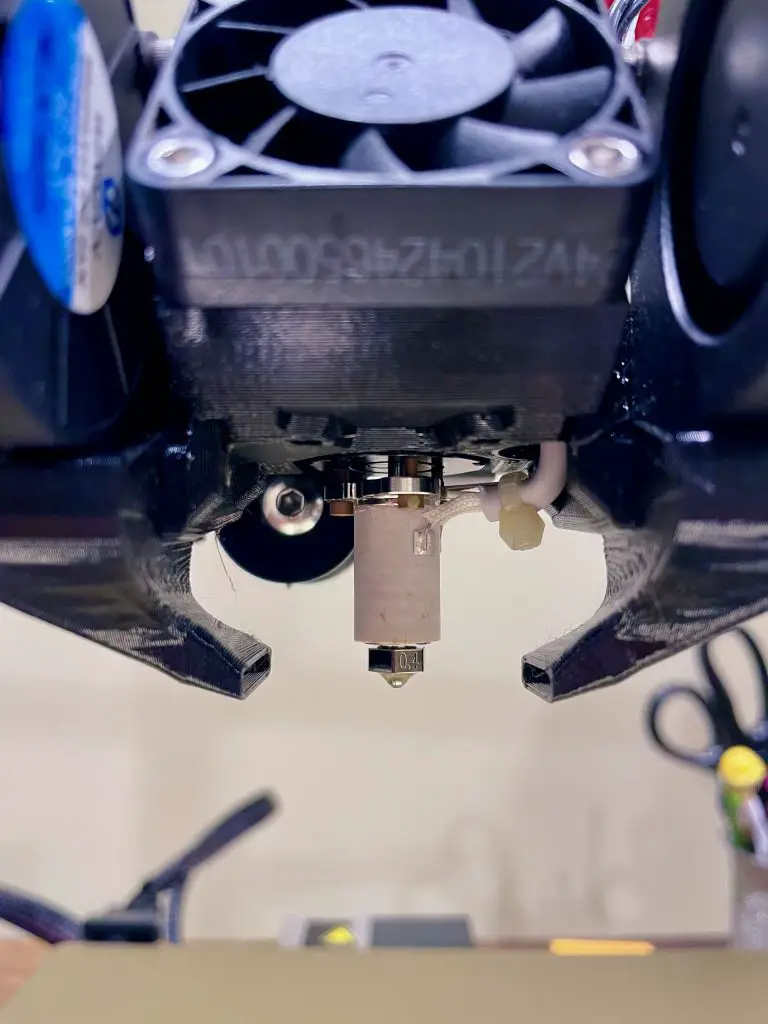

- 【Uniform Heating】:Thanks to the cylindrical ceramic heating unit, the hotend heats up more evenly.

- 【Optimised structure of the integral frame】:The rigid structure of the integral frame made of titanium alloy screws enables a lower thermal conductivity and enables one-handed nozzle change.

- 【Thin-walled heat break】:A thin-walled heat break prevents heat creep and clogging while also providing excellent thermal insulation.

My friend Nathan, of Nathan Builds Robots, did a great review on this hotend.

How fast does the Phaetus Rapdio heat?

SO FAST… I was stunned. On my stock hotend I’d set it to heat and wait several minutes.

On the Phaetus?

Turned it on, set to 200°C, and watched (each interval was about 3-5 seconds):

22°C. 35°C. 80°C. 150°C. 212°C (overshot… see the important tuning the PID section below).

How difficult is it to install the Phaetus Rapido

Plan on a multi-hour conversion if you’re installing it on a Creality printer (such as the Ender 3 V2) as the Phaetus uses a “V6” style mount.

This means you’ll need to buy/print a new mounting system for the Phaetus, so I took that time to upgrade my fans to the HeroMe Gen 6 cooling system.

Note: I chose the HeroMe because it explicitly supports the Phaetus. However, the build sucks so hard that I’d recommend trying the compact “Manta” system for a Creality Ender 3, 5, or CR 10.

Once mounted the rest of the build was pretty easy. I spliced in new wires using red quick disconnects, auto-tuned my PID (see below), and was good to go.

How to autotune your Phaetus PID

This is the guide I used to tune my PID on the stock (Marlin) firmware.

If you’ve already upgraded to Klipper then I’m positive you could handle this without my help.