If you’re just getting into 3D printing the filament names can start to feel like a forest of acronyms. PCL, PLA, ABS, NBC, ABC, etc. (ok the last two are broadcasting companies, also I hate acronyms).

But I keep running into both PCL and PLA, especially using my 3D pens.

So…

What is the difference between PCL and PLA filaments?

In a nutshell, PCL (Polycaprolactone), is a biodegradable polyester with a very low melting point of 60° C (140° F) while PLA (Poly Lactic Acid) is a renewable plastic made from food starches with a melting point of ~175° C.

The melting point and strength characteristics of PLA

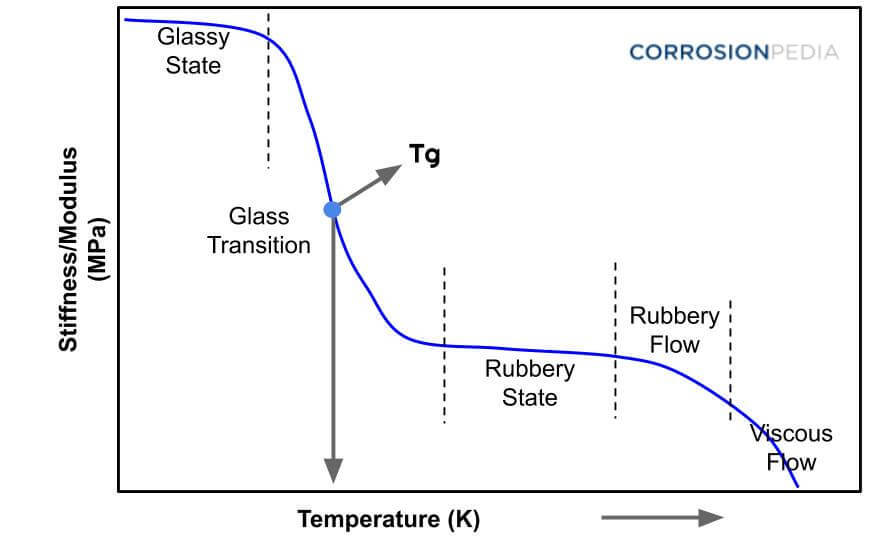

PLA has a glass transition temperature between 60 and 80 °C and a melting temperature between 170 and 180 °C.

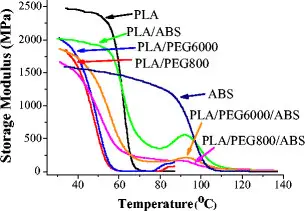

This means that PLA will keep most of its strength characteristics up until 60 °C (122 °F), after which it’ll start to lose strength (it’s “storage modulus”)… in short, standard PLA is only useful until about 60 °C.

The melting point and strength characteristics of PCL

PCL has a melting point of 60 °C and a glass transition temperature of -60 °C (-76 °F). This means PCL at room temperature is “rubbery” – it can be bent, flexed, and pulled apart (with some effort) with no additional heating.

This means that PCL is not good (at all!) for anything that needs to hold weight. It also means that you can extrude PCL right onto your hand and, due to the low melting point, probably not get burned – making it fantastic for kids.

Is PLA biodegradable

Not really. PLA can be degraded in industrial composting facilities by heating it to 140 °C and adding special enzymes to it. So while it can be composted or degraded, it usually ends up in a landfill where PLA can take 100 to 1000 years to degrade.

Is PCL biodegradable

Yes, PCL is biodegradable and will typically break down in 2 to 4 years.

In conclusion: when to use PCL vs PLA

PCL is great in 3D printing pens for kids (and artistic adults!) or when you need a rubbery material that won’t take much stress. It’s also not bioactive, is FDA approved for use in implantable medical devices and will biodegrade in 1-2 years, making it a wonderful material for many low to non-load bearing applications.

If you’re drawing with a 3D pen, PCL is a great material to start with as it’s dead simple to use, flows nicely, and won’t leave you with burns.

PLA is a great all-around material for 3D printing (see our list of best PLA filaments here). While the one major downside of PLA is the it is not biodegradable and most of it ends up in landfills where it sits for many, many years, it’s made of natural starches, the odors it emits smell like cooked pancakes, it has decent mechanical properties, and it’s cheap-ish.

PLA can also be made non-bioactive (like PCL) – though you’d need special formulations for it.

If you’re 3D printing, PLA is your best starting material. Of course, getting PLA to stick to your 3D printing bed, smoothing PLA, or gluing PLA together are all topics for their own posts.