When you have low quality filament or a misaligned PTFE tube, it’s possible that filament may break and get stuck inside the PTFE tube. Getting the filament out is pretty straightforward, so let’s dive in.

How to remove filament stuck in the PTFE tube

The easiest way to remove filament stuck in your 3D printer’s PTFE tube is to remove the tube from the printer and insert a thin wire or some fresh filament into the tube to push the stuck filament out. If the filament is really hard, submerge the tube in boiling water to soften the filament, then push it out with a wire or fresh filament.

Where can filament get stuck?

On the whole, there are two places that filament can stuck in the PTFE tube.

- If you’re using a Bowden extruder, the filament can get stuck anywhere along the entire Bowden tube from the extruder to the hot end

- If you’re using a direct drive extruder, the hot end sometimes has a small piece of PTFE tubing right before the heat break

Why does filament get stuck in the PTFE tube?

In Bowden setups, the filament usually gets stuck due to poor quality filament that breaks or snaps during a print. You may also end up breaking filament in the tube if you try to remove the PTFE tubing from the extruder with filament still in it.

Stuck filament can also happen if the Bowden tube moves up and down during retraction and the filament oozes out of the tube before going into the heatbreak,

This is also why filament gets stuck in the PTFE tubing in direct drive setups: if the tubing is misaligned, the filament can ooze out and get stuck in the tubing.

How to remove filament stuck in a Bowden tube

To remove filament stuck in a Bowden tube, you need to first remove the tube from the extruder and the hot end.

- Press down on the black/blue collet ring on the extruder coupling to release the Bowden tube. With the collet ring still pressed down, gently pull the tube out of the extuder.

- Repeat this process for the hot end. If the tube does not come out, it’s likely that there is filament stuck at the end of the tubing which is preventing it from coming out. Skip to the next section for this fix.

- With the Bowden tube completely removed, place it in a vice or hold it tightly and use a wire or another filament to push the stuck filament out.

- Once the filament is out, press down on the collect and slide the Bowden tube back in. Slide it in all the way.

- Repeat for the hot end

How to remove filament stuck in the hot end’s PTFE tube

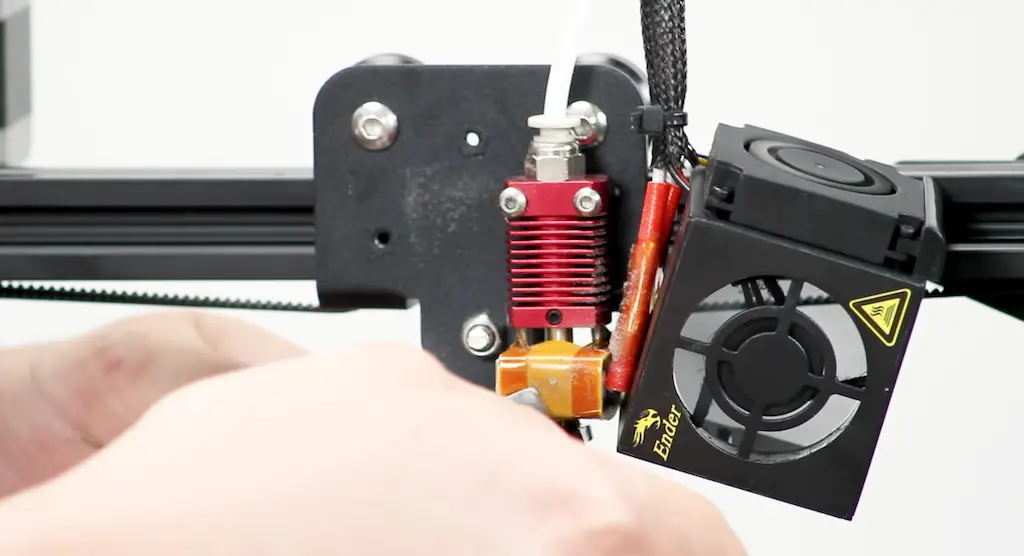

If filament is stuck in the hot end, you’ll have to disassmble the hot end to access it.

- Make sure the 3D printer is not running and the nozzle is cool

- Grab the heat block with one set of pliers, and use another set of pliers or a hex ratchet to unscrew the nozzle from the hot end.

- Unscrew the heating block from the heatsink (Some manufacturers use an adhesive to screw on the nozzle. If this is the case, you’ll need to raise the hot end temperature to loosen it and unscrew the nozzle. Do this with extreme care to not burn yourself).

- Remove the heat break(thin metal tube) from the heating block

- Remove the PTFE tubing from the heat break

- Push filament out with a wire or other filament

- Replace PTFE tube in heat break

- Screw the PTFE tube back onto the heat block

- Screw the heat block back onto the heat sink

- Screw the nozzle back on

Credit: Youtube | 3D Printing Canada

How to remove filament stuck between the PTFE tube and the nozzle

This type of stuck filament is the toughest to remove, as you can’t just push it out.

- Detach the hot end from the 3D printer body

- Remove the heat sink from the heating block assembly

- If the PTFE tube is stuck, remove the nozzle using a set of pliers or a hex ratchet

- Use a hot air gun or small blowtorch at the nozzle’s hole to melt/burn the filament out

- Wait for everything to cool, and replace the nozzle

- Remove the PTFE tube and make sure it’s clean, then place it back in

- Assemble the hot end and reattach to your 3D printer

Conclusion

Prevention is always better than cure, so make sure you use high quality filaments that don’t break quite as easily.

Also, before you start using your 3D printer, make sure the PTFE tubing is seated in all the way, otherwise you will run the risk of a leak.

Making sure the coupler is strong will prevent the PTFE tube from unnecessarily moving during retractions.

Finally, make sure the PTFE tube is sound(exposing it to high temperatures can cause it to deform) and that the bends in it are not too tight. That can add unnecessary strain to the filament and tubing.